Operations Abbreviations: Key Terms [Guide]

Written by

Ernest Bio Bogore

Reviewed by

Ibrahim Litinine

![Operations Abbreviations: Key Terms [Guide]](/_next/image?url=https%3A%2F%2Fcdn.sanity.io%2Fimages%2F147z5m2d%2Fproduction%2Fddfd99ed113a141100a2b894cacf8a4397582ec9-2240x1260.png&w=3840&q=75)

Operations teams juggle countless processes, methodologies, and systems daily. Each comes with its own set of abbreviations that can confuse newcomers and seasoned professionals alike. Understanding these abbreviations isn't just about decoding corporate jargon—it's about communicating effectively in fast-paced business environments.

Operations abbreviations serve as shorthand for complex concepts, enabling teams to discuss intricate processes without lengthy explanations. From supply chain management to quality control, these terms form the backbone of operational communication across industries. In this article, we'll decode the most critical operations abbreviations, explain their contexts, and show you how to use them appropriately in professional settings.

Essential Daily Operations Abbreviations

Operations professionals encounter certain abbreviations so frequently they become second nature. These fundamental terms appear in emails, reports, meetings, and strategic discussions across virtually every industry. Understanding them is crucial for anyone working in or with operations teams.

SOP (Standard Operating Procedure) represents documented processes that teams follow to ensure consistency and quality. Every operations department relies on SOPs to maintain standards, whether for manufacturing assembly lines or customer service protocols. When someone mentions "following SOP," they're referencing established procedures that shouldn't be deviated from without proper authorization.

KPI (Key Performance Indicator) measures operational success against predetermined goals. Operations managers track KPIs to assess efficiency, quality, and productivity. Common operational KPIs include cycle time, defect rates, and throughput measurements. These metrics drive decision-making and resource allocation across operations teams.

ERP (Enterprise Resource Planning) systems integrate various business processes into unified platforms. Operations teams use ERP systems to manage inventory, track orders, coordinate production schedules, and analyze performance data. Major ERP solutions like SAP, Oracle, and Microsoft Dynamics have become indispensable for modern operations management.

WMS (Warehouse Management System) specifically handles inventory storage, movement, and tracking within warehouse facilities. Unlike broader ERP systems, WMS focuses exclusively on warehouse operations, optimizing space utilization, picking routes, and inventory accuracy. Distribution centers and fulfillment operations depend heavily on WMS functionality.

MRP (Material Requirements Planning) calculates material needs based on production schedules and demand forecasts. Manufacturing operations use MRP to determine when to order raw materials, how much inventory to maintain, and when to schedule production runs. This abbreviation often appears in discussions about supply chain planning and inventory optimization.

These everyday abbreviations form the foundation of operational communication. Teams use them assuming shared understanding, making familiarity essential for effective collaboration and professional credibility.

Supply Chain and Logistics Operations Abbreviations

Supply chain operations have developed their own extensive vocabulary of abbreviations, reflecting the complexity of moving goods from suppliers to customers. These terms encompass procurement, transportation, warehousing, and distribution activities that keep global commerce functioning.

SCM (Supply Chain Management) encompasses all activities involved in sourcing, procurement, conversion, and logistics management. Operations professionals use SCM when discussing end-to-end supply chain strategy, vendor relationships, and process optimization. Effective SCM requires coordination between multiple departments and external partners.

3PL (Third-Party Logistics) providers handle logistics operations on behalf of other companies. When operations teams mention 3PL partnerships, they're discussing outsourced warehousing, transportation, or distribution services. Companies like FedEx Supply Chain, DHL, and XPO Logistics represent major 3PL providers that operations teams frequently work with.

4PL (Fourth-Party Logistics) takes outsourcing further by managing entire supply chain networks, including multiple 3PL providers. Operations executives consider 4PL arrangements when seeking comprehensive supply chain management without internal resource investment. These relationships involve strategic partnership rather than simple service provision.

LTL (Less Than Truckload) shipping consolidates smaller shipments from multiple customers into single truck loads. Operations teams use LTL services when shipment volumes don't justify full truckload transportation. This abbreviation appears frequently in transportation planning and cost optimization discussions.

FTL (Full Truckload) represents shipments large enough to occupy entire truck trailers. Operations managers choose FTL when shipping volumes, delivery requirements, or security concerns justify dedicated transportation. The decision between LTL and FTL significantly impacts transportation costs and delivery schedules.

EDI (Electronic Data Interchange) enables automated document exchange between trading partners. Operations teams rely on EDI for purchase orders, invoices, shipping notices, and inventory updates. This technology eliminates manual data entry and reduces processing errors in supply chain transactions.

VMI (Vendor Managed Inventory) arrangements allow suppliers to monitor and replenish customer inventory automatically. Operations managers implement VMI to reduce inventory carrying costs while ensuring stock availability. These partnerships require high trust levels and sophisticated data sharing capabilities.

JIT (Just-In-Time) inventory management minimizes stock levels by receiving materials precisely when needed for production. Operations teams pursuing JIT must coordinate closely with suppliers to ensure reliable delivery schedules. This approach reduces inventory costs but increases supply chain risk.

Supply chain abbreviations reflect the interconnected nature of modern commerce, where operations success depends on seamless coordination between multiple organizations and systems.

Quality Management and Process Improvement Abbreviations

Quality management has evolved into a discipline with extensive abbreviation usage, reflecting decades of methodology development and continuous improvement practices. Operations teams implementing quality systems must navigate this specialized vocabulary to communicate effectively about standards, processes, and improvement initiatives.

QMS (Quality Management System) represents comprehensive frameworks for managing quality across all organizational processes. Operations departments implement QMS to ensure consistent product and service quality while meeting regulatory requirements. ISO 9001 represents the most widely recognized QMS standard globally.

Six Sigma methodology uses statistical analysis to identify and eliminate defects in processes. Operations professionals pursuing Six Sigma certification learn to apply DMAIC (Define, Measure, Analyze, Improve, Control) methodology for systematic problem-solving. Green Belt and Black Belt certifications indicate different proficiency levels in Six Sigma application.

Lean Manufacturing focuses on waste elimination and value stream optimization. Operations teams applying Lean principles identify and eliminate eight types of waste: transportation, inventory, motion, waiting, overproduction, overprocessing, defects, and skills underutilization. Lean implementation often precedes or accompanies Six Sigma initiatives.

TQM (Total Quality Management) represents organization-wide commitment to quality improvement through employee involvement and customer focus. Operations managers implementing TQM create cultures where quality responsibility extends beyond dedicated quality departments to all organizational levels.

SPC (Statistical Process Control) uses statistical methods to monitor and control process performance. Operations teams apply SPC to detect process variations before they result in defective products. Control charts, capability studies, and process monitoring represent common SPC applications.

FMEA (Failure Mode and Effects Analysis) systematically identifies potential failure points and their consequences. Operations engineers use FMEA during product development and process design to prevent problems rather than react to them. This proactive approach reduces quality issues and associated costs.

CAPA (Corrective and Preventive Action) processes address quality issues through systematic root cause analysis and solution implementation. Operations teams document CAPA activities to demonstrate continuous improvement efforts and regulatory compliance. These processes ensure problems don't recur once identified and resolved.

OEE (Overall Equipment Effectiveness) measures equipment performance across availability, performance, and quality dimensions. Operations managers use OEE to identify improvement opportunities and track maintenance effectiveness. World-class OEE performance typically exceeds 85% across all three dimensions.

Quality management abbreviations reflect the systematic approach required for operational excellence, emphasizing measurement, analysis, and continuous improvement as core operational competencies.

Project Management and Planning Operations Abbreviations

Operations teams increasingly rely on project management methodologies to implement improvements, manage changes, and deliver results within specified timeframes and budgets. These abbreviations reflect both traditional and agile project management approaches adapted for operational environments.

PMO (Project Management Office) provides centralized support, standards, and oversight for organizational projects. Operations departments often establish PMOs to ensure consistent project delivery methodologies and resource allocation. PMOs also facilitate knowledge sharing and best practice development across project teams.

WBS (Work Breakdown Structure) decomposes complex projects into manageable components and tasks. Operations project managers use WBS to estimate resources, assign responsibilities, and track progress against deliverables. Effective WBS development ensures comprehensive project scope coverage without overlap or gaps.

GANTT Charts visually represent project schedules, showing task dependencies, durations, and resource assignments. Operations teams use GANTT charts to communicate project timelines, identify critical paths, and coordinate resource allocation. Modern project management software automatically generates GANTT charts from task and dependency data.

PERT (Program Evaluation and Review Technique) analyzes project schedules considering task duration uncertainty. Operations managers apply PERT when project timing involves significant uncertainty or when schedule risk assessment is critical. PERT calculations provide probabilistic project completion estimates rather than fixed dates.

RACI Matrix clarifies roles and responsibilities for project activities and decisions. Operations teams use RACI (Responsible, Accountable, Consulted, Informed) matrices to eliminate confusion about who performs tasks, makes decisions, provides input, and receives updates. Clear role definition prevents project delays and conflicts.

MVP (Minimum Viable Product) represents the simplest version of a solution that delivers value to users. Operations teams adopting agile approaches implement MVPs to test concepts quickly and gather feedback before full-scale deployment. This approach reduces development costs and implementation risks.

ROI (Return on Investment) calculates financial returns from project investments. Operations managers must demonstrate ROI to justify project approval and resource allocation. ROI calculations consider both direct costs and indirect benefits like efficiency improvements and risk reduction.

NPV (Net Present Value) evaluates project profitability considering time value of money. Operations executives use NPV analysis for capital investment decisions and project prioritization. Projects with positive NPV create shareholder value, while negative NPV projects destroy value.

Project management abbreviations enable operations teams to discuss complex initiatives using shared terminology, facilitating better communication and more effective project delivery.

Technology and Automation Operations Abbreviations

Modern operations increasingly depend on technology solutions that automate processes, provide real-time visibility, and enable data-driven decision-making. These technological abbreviations reflect the digital transformation occurring across operations functions worldwide.

IoT (Internet of Things) connects physical devices to networks for data collection and remote control. Operations teams implement IoT sensors to monitor equipment performance, track asset locations, and optimize maintenance schedules. Smart factories rely extensively on IoT infrastructure for automated operations management.

AI (Artificial Intelligence) and ML (Machine Learning) enable systems to learn from data and make autonomous decisions. Operations departments apply AI for demand forecasting, predictive maintenance, quality inspection, and process optimization. ML algorithms continuously improve their performance as they process more operational data.

RPA (Robotic Process Automation) automates repetitive, rule-based tasks typically performed by humans. Operations teams implement RPA for data entry, report generation, invoice processing, and compliance monitoring. RPA deployment frees human resources for higher-value activities while improving accuracy and speed.

API (Application Programming Interface) enables different software systems to communicate and share data. Operations managers rely on APIs to integrate various systems, from ERP platforms to warehouse management systems. API connectivity eliminates data silos and enables real-time information sharing across operations.

Cloud Computing provides scalable, on-demand access to computing resources and applications. Operations teams increasingly migrate to cloud-based solutions for flexibility, cost reduction, and accessibility. Cloud platforms support remote operations management and enable rapid scaling during demand fluctuations.

SaaS (Software as a Service) delivers applications through web browsers rather than local installations. Operations departments adopt SaaS solutions for project management, inventory tracking, and performance monitoring. SaaS platforms reduce IT infrastructure requirements while providing automatic updates and maintenance.

Dashboard interfaces provide real-time visibility into operational performance through visual displays. Operations managers use dashboards to monitor KPIs, identify trends, and respond quickly to emerging issues. Effective dashboards present relevant information clearly without overwhelming users with excessive detail.

Analytics Platforms process large datasets to identify patterns, trends, and optimization opportunities. Operations teams use analytics to improve forecasting accuracy, optimize resource allocation, and enhance decision-making quality. Advanced analytics capabilities include predictive modeling and scenario analysis.

Technology abbreviations reflect the ongoing digital transformation of operations management, where traditional processes increasingly incorporate smart systems and automated decision-making capabilities.

Financial Operations and Budgeting Abbreviations

Operations management intersects significantly with financial planning and control, requiring familiarity with accounting and budgeting terminology. These abbreviations appear frequently in budget discussions, performance reviews, and strategic planning sessions.

CAPEX (Capital Expenditure) represents investments in long-term assets like equipment, facilities, and technology. Operations managers develop CAPEX budgets for infrastructure improvements, automation projects, and capacity expansion. CAPEX decisions require careful ROI analysis and approval from senior management.

OPEX (Operating Expenditure) covers day-to-day operational costs including labor, materials, utilities, and maintenance. Operations teams manage OPEX budgets to control ongoing costs while maintaining service levels. OPEX optimization often focuses on efficiency improvements and waste reduction.

TCO (Total Cost of Ownership) calculates comprehensive costs associated with assets throughout their useful lives. Operations managers use TCO analysis for equipment selection, outsourcing decisions, and technology investments. TCO includes purchase price, maintenance costs, training expenses, and disposal costs.

ABC (Activity-Based Costing) allocates overhead costs based on actual resource consumption by different activities. Operations teams use ABC to understand true product costs and identify improvement opportunities. This costing method provides more accurate profitability analysis than traditional overhead allocation methods.

P&L (Profit and Loss) statements summarize operational financial performance over specific periods. Operations managers review P&L statements to understand revenue generation, cost structures, and profitability trends. These reports guide operational decision-making and resource allocation.

EBITDA (Earnings Before Interest, Taxes, Depreciation, and Amortization) measures operational profitability excluding financing and accounting effects. Operations executives use EBITDA to evaluate operational efficiency and compare performance across different periods or business units.

Working Capital represents short-term assets minus short-term liabilities, indicating operational liquidity. Operations managers influence working capital through inventory management, payment terms negotiation, and collection period optimization. Efficient working capital management improves cash flow and reduces financing costs.

Budget Variance Analysis compares actual performance against planned budgets to identify deviations and their causes. Operations teams conduct variance analysis to understand performance gaps and implement corrective actions. Regular variance analysis ensures operational performance aligns with financial expectations.

Financial operations abbreviations enable clear communication between operations and finance teams, facilitating better resource allocation and performance management across organizational boundaries.

Regulatory Compliance and Safety Operations Abbreviations

Operations in many industries must navigate complex regulatory environments while maintaining workplace safety standards. These abbreviations reflect the compliance and safety frameworks that operations teams must understand and implement.

OSHA (Occupational Safety and Health Administration) establishes and enforces workplace safety standards in the United States. Operations managers must ensure OSHA compliance through hazard identification, safety training, and incident reporting. OSHA violations can result in significant fines and operational disruptions.

ISO (International Organization for Standardization) develops global standards for quality, environmental management, and safety. Operations teams implement ISO standards to demonstrate compliance, improve processes, and access international markets. Common operational ISO standards include 9001 (quality), 14001 (environmental), and 45001 (occupational health and safety).

HACCP (Hazard Analysis and Critical Control Points) provides systematic approaches for food safety management. Food operations implement HACCP to identify biological, chemical, and physical hazards throughout production processes. HACCP compliance is mandatory for many food processing and distribution operations.

GMP (Good Manufacturing Practice) establishes minimum requirements for pharmaceutical, food, and cosmetic manufacturing. Operations teams follow GMP guidelines to ensure product safety, quality, and efficacy. GMP compliance requires documented procedures, facility design standards, and personnel training.

MSDS (Material Safety Data Sheet) provides hazard information for chemical substances used in operations. Operations managers ensure MSDS availability for all hazardous materials to protect worker safety and ensure emergency response preparedness. MSDS information includes handling procedures, storage requirements, and first aid measures.

PPE (Personal Protective Equipment) includes safety gear required for hazardous operations. Operations supervisors ensure appropriate PPE availability, training, and usage across all work areas. PPE requirements vary based on specific hazards present in different operational environments.

SDS (Safety Data Sheet) represents the updated format for chemical hazard communication, replacing traditional MSDS formats. Operations teams maintain current SDS for all chemicals to ensure compliance with global harmonization standards and worker protection requirements.

Environmental Compliance encompasses regulations governing waste disposal, emissions, and resource usage. Operations managers must understand environmental requirements and implement systems for monitoring, reporting, and continuous improvement. Non-compliance can result in significant penalties and reputational damage.

Regulatory and safety abbreviations reflect the critical importance of compliance in modern operations, where legal requirements and safety standards significantly influence operational design and execution.

Performance Measurement and Analytics Operations Abbreviations

Data-driven operations management relies on sophisticated measurement systems and analytical approaches to optimize performance and drive continuous improvement. These abbreviations reflect the evolution of operations analytics from basic reporting to advanced predictive modeling.

BPM (Business Process Management) encompasses methodologies for designing, executing, monitoring, and optimizing business processes. Operations teams use BPM platforms to model workflows, automate approvals, and track process performance. BPM enables systematic process improvement and organizational agility.

BI (Business Intelligence) transforms operational data into actionable insights through reporting, dashboards, and analytics. Operations managers rely on BI tools to identify trends, monitor performance, and support decision-making. Modern BI platforms provide self-service analytics capabilities for operations professionals.

Benchmarking compares operational performance against industry standards, competitors, or best practices. Operations teams conduct benchmarking studies to identify improvement opportunities and set realistic performance targets. External benchmarking requires careful data collection and analysis methodology.

Balanced Scorecard frameworks measure performance across financial, customer, internal process, and learning perspectives. Operations organizations use balanced scorecards to align activities with strategic objectives and ensure comprehensive performance evaluation. This approach prevents overemphasis on short-term financial results.

Process Mining analyzes event logs from operational systems to discover actual process flows and identify optimization opportunities. Operations teams apply process mining to understand how work actually gets done versus documented procedures. This analysis reveals bottlenecks, variations, and improvement possibilities.

Predictive Analytics uses historical data and statistical models to forecast future operational outcomes. Operations managers apply predictive analytics for demand forecasting, maintenance scheduling, and quality prediction. These capabilities enable proactive management rather than reactive problem-solving.

Real-time Monitoring provides immediate visibility into operational performance through continuous data collection and analysis. Operations control centers use real-time monitoring to detect problems quickly and coordinate response efforts. This capability is essential for time-sensitive operations and customer service.

Data Visualization presents complex operational data through charts, graphs, and interactive displays. Operations teams use visualization tools to communicate performance information effectively and identify patterns that might be missed in tabular data. Good visualization design enhances decision-making speed and accuracy.

Performance measurement abbreviations reflect the increasing sophistication of operations analytics, where traditional reporting has evolved into comprehensive business intelligence platforms supporting data-driven operational excellence.

Cultural Nuances in Operations Abbreviation Usage

Operations abbreviations carry contextual meanings that extend beyond their literal definitions, reflecting organizational cultures, industry practices, and professional relationships. Understanding these nuances is crucial for effective communication within operations teams and across organizational boundaries.

Different industries emphasize different abbreviations based on their operational priorities and regulatory requirements. Manufacturing operations heavily use quality-focused abbreviations like Six Sigma, Lean, and OEE, while service operations might emphasize customer-related metrics and process efficiency measures. Healthcare operations incorporate patient safety and regulatory compliance abbreviations, while financial services operations focus on risk management and audit-related terminology.

Organizational maturity levels influence abbreviation usage patterns. Established companies with formal operations management structures use comprehensive abbreviation sets reflecting sophisticated processes and systems. Startup organizations might focus on agile methodology abbreviations and growth-oriented metrics. Understanding an organization's operational maturity helps gauge appropriate abbreviation usage in different contexts.

Professional relationships affect abbreviation usage formality and complexity. Communications with senior executives might emphasize strategic abbreviations like ROI, NPV, and EBITDA, while front-line discussions focus on operational abbreviations like SOP, KPI, and OEE. Cross-functional communications require careful abbreviation selection to ensure understanding across different departmental backgrounds.

Global operations add complexity through regional variations in abbreviation usage and interpretation. European operations might emphasize ISO standards and environmental compliance, while North American operations focus on OSHA safety requirements and SEC financial reporting. Asian operations often integrate traditional manufacturing excellence approaches with modern digital transformation initiatives.

Generation differences also influence abbreviation preferences and understanding. Experienced operations professionals might prefer traditional manufacturing and quality management abbreviations, while younger professionals gravitate toward technology and analytics-focused terminology. Effective operations communication bridges these generational preferences through inclusive abbreviation usage.

Advanced Operations Strategy Abbreviations

Strategic operations management has developed specialized terminology reflecting complex decision-making frameworks and competitive positioning concepts. These abbreviations appear in executive discussions, strategic planning sessions, and operational transformation initiatives.

SCOR (Supply Chain Operations Reference) model provides standardized frameworks for supply chain process design and performance measurement. Operations executives use SCOR to benchmark performance, identify improvement opportunities, and communicate supply chain strategies. The model covers plan, source, make, deliver, return, and enable processes.

TOC (Theory of Constraints) focuses improvement efforts on system bottlenecks that limit overall performance. Operations managers apply TOC principles to identify constraints, optimize constraint utilization, and systematically improve system capacity. This approach ensures improvement investments target actual performance limitations.

Mass Customization strategies enable efficient production of customized products through flexible manufacturing and supply chain systems. Operations teams implement mass customization through modular design, postponement strategies, and configure-to-order processes. This capability provides competitive advantage in markets demanding product variety.

Agility represents organizational capability to respond quickly to market changes and customer requirements. Operations leaders develop agility through flexible capacity, responsive supply chains, and adaptive processes. Agile operations can capitalize on opportunities and minimize disruption from unexpected changes.

Sustainability encompasses environmental, social, and economic considerations in operations strategy and execution. Operations managers implement sustainable practices through waste reduction, energy efficiency, and ethical sourcing. Sustainability considerations increasingly influence operational decision-making and stakeholder expectations.

Digital Transformation represents comprehensive integration of digital technologies into all operational aspects. Operations executives lead digital transformation through process automation, data analytics implementation, and workforce capability development. This transformation fundamentally changes how operations create and deliver value.

Strategic abbreviations reflect the evolution of operations management from tactical execution to strategic value creation, where operational excellence becomes a source of competitive advantage and organizational resilience.

How to Say Operations Abbreviations FAQ

What does SOP stand for in operations?

SOP stands for Standard Operating Procedure, which refers to documented step-by-step instructions for completing routine operational tasks. SOPs ensure consistency, quality, and compliance across operations teams by providing standardized approaches for common activities.

How do you pronounce ERP in operations contexts?

ERP is pronounced as individual letters "E-R-P" rather than as a word. It stands for Enterprise Resource Planning, representing integrated software systems that manage various business processes including operations, finance, and human resources.

What's the difference between 3PL and 4PL in logistics?

3PL (Third-Party Logistics) providers handle specific logistics functions like warehousing or transportation for other companies. 4PL (Fourth-Party Logistics) providers manage entire supply chain networks, including coordinating multiple 3PL providers and serving as single points of contact for comprehensive logistics management.

When should operations teams use Lean versus Six Sigma?

Lean methodology focuses on waste elimination and flow improvement, making it ideal for process streamlining and efficiency enhancement. Six Sigma emphasizes defect reduction and variation control through statistical analysis, making it suitable for quality improvement and problem-solving. Many organizations combine both approaches for comprehensive operational excellence.

What does OEE measure in manufacturing operations?

OEE (Overall Equipment Effectiveness) measures manufacturing equipment performance across three dimensions: Availability (scheduled versus actual operating time), Performance (actual versus theoretical production rates), and Quality (good parts versus total parts produced). World-class OEE typically exceeds 85%.

How do operations teams use KPIs effectively?

Effective KPI usage requires selecting metrics that align with strategic objectives, setting realistic but challenging targets, ensuring data accuracy and timeliness, and regularly reviewing performance to drive improvement actions. KPIs should be specific, measurable, achievable, relevant, and time-bound.

What's the significance of ISO standards in operations?

ISO standards provide internationally recognized frameworks for quality management, environmental management, and safety management. Operations teams implement ISO standards to demonstrate compliance, improve processes, access global markets, and enhance customer confidence in their capabilities.

How do cloud computing abbreviations impact operations?

Cloud computing abbreviations like SaaS (Software as a Service), IaaS (Infrastructure as a Service), and PaaS (Platform as a Service) represent different levels of cloud service provision. Operations teams use these services to reduce IT infrastructure costs, improve scalability, and enable remote operations management.

Understanding these abbreviations and their proper usage enables more effective communication within operations teams and across organizational boundaries, ultimately supporting better operational performance and professional development.

Learn Any Language with Kylian AI

Private language lessons are expensive. Paying between 15 and 50 euros per lesson isn’t realistic for most people—especially when dozens of sessions are needed to see real progress.

Many learners give up on language learning due to these high costs, missing out on valuable professional and personal opportunities.

That’s why we created Kylian: to make language learning accessible to everyone and help people master a foreign language without breaking the bank.

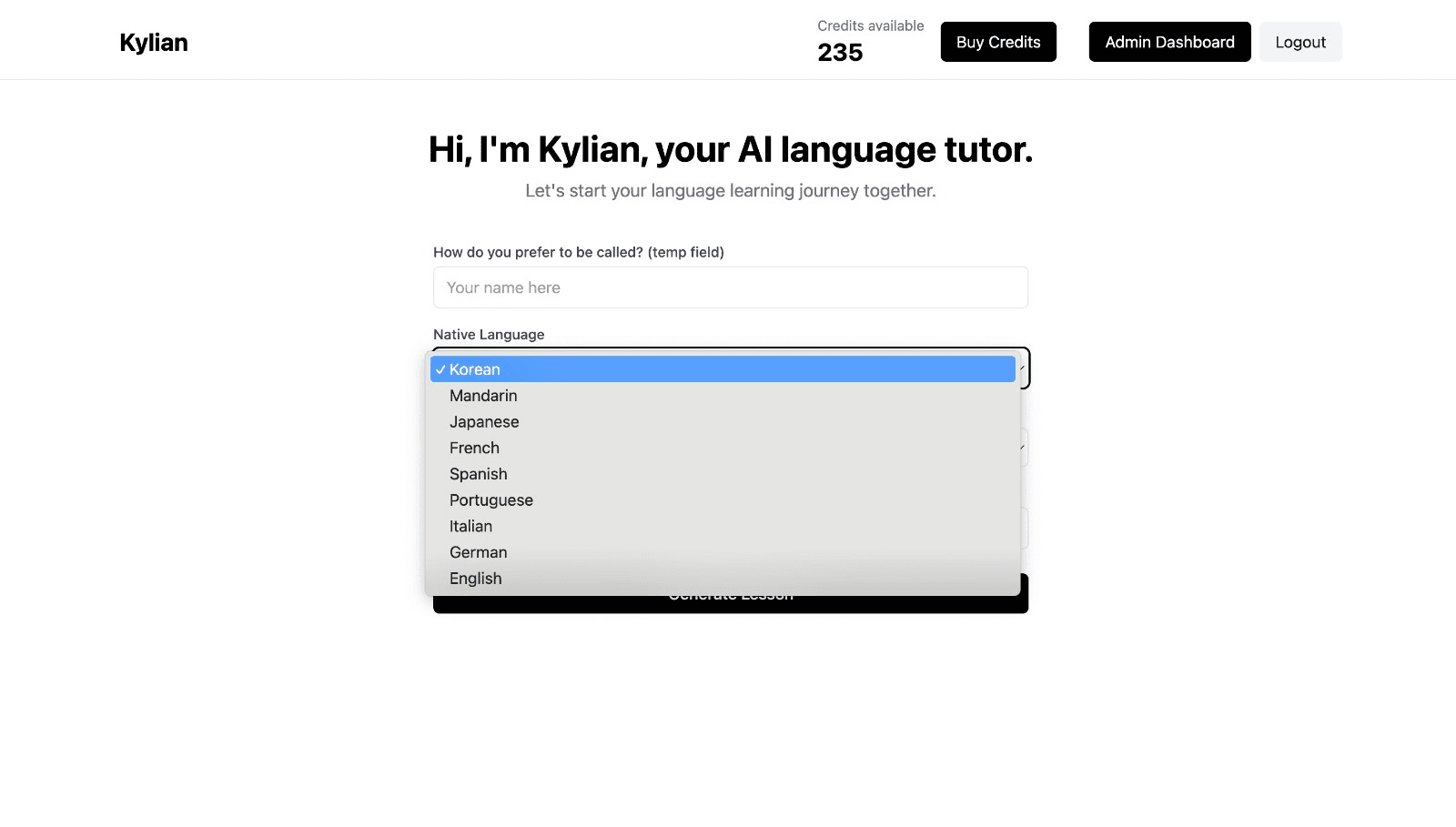

To get started, just tell Kylian which language you want to learn and what your native language is

Tired of teachers who don’t understand your specific struggles as a French speaker? Kylian’s advantage lies in its ability to teach any language using your native tongue as the foundation.

Unlike generic apps that offer the same content to everyone, Kylian explains concepts in your native language (French) and switches to the target language when necessary—perfectly adapting to your level and needs.

This personalization removes the frustration and confusion that are so common in traditional language learning.

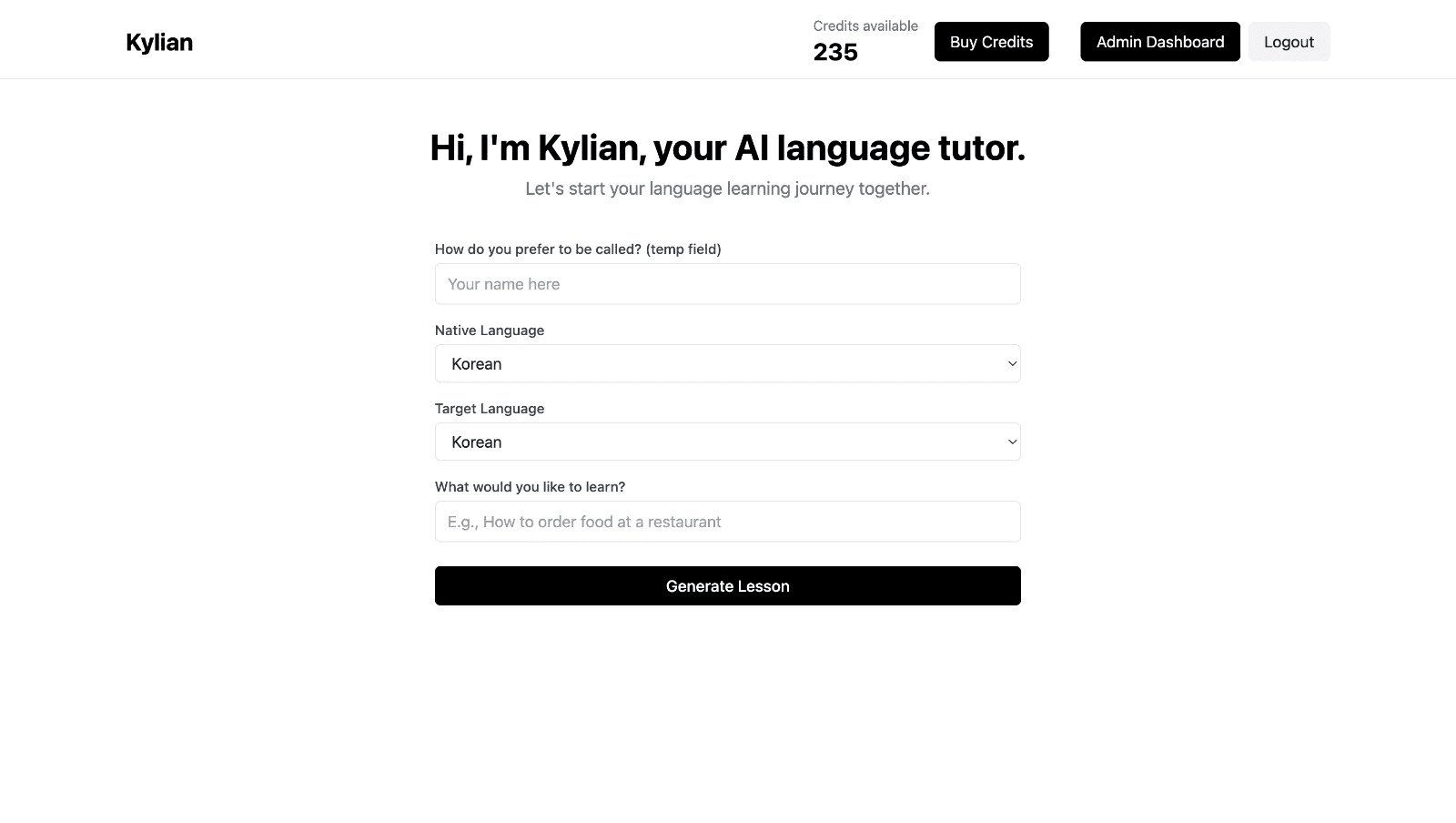

Choose a specific topic you want to learn

Frustrated by language lessons that never cover exactly what you need? Kylian can teach you any aspect of a language—from pronunciation to advanced grammar—by focusing on your specific goals.

Avoid vague requests like “How can I improve my accent?” and be precise: “How do I pronounce the R like a native English speaker?” or “How do I conjugate the verb ‘to be’ in the present tense?”

With Kylian, you’ll never again pay for irrelevant content or feel embarrassed asking “too basic” questions to a teacher. Your learning plan is entirely personalized.

Once you’ve chosen your topic, just hit the “Generate a Lesson” button, and within seconds, you’ll get a lesson designed exclusively for you.

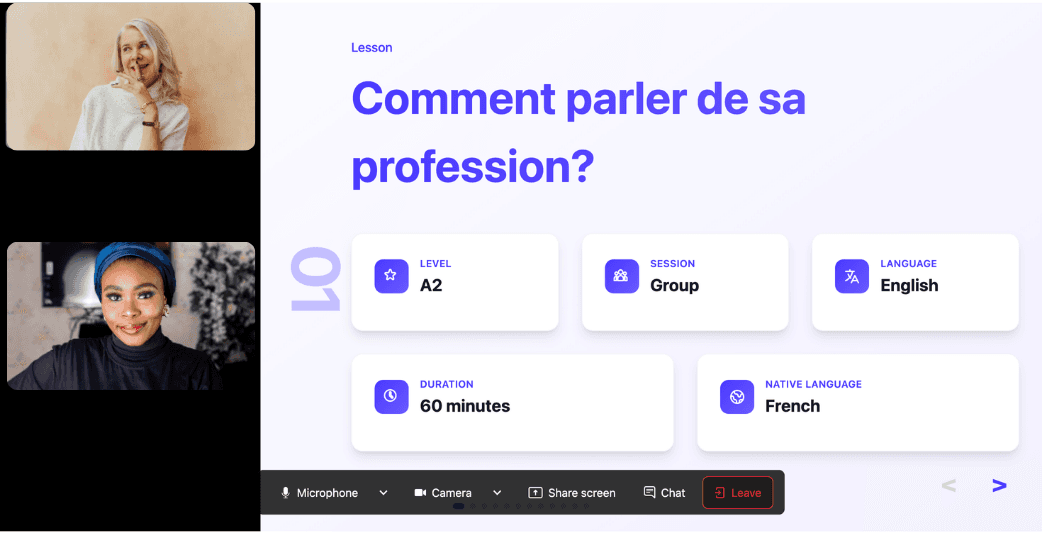

Join the room to begin your lesson

The session feels like a one-on-one language class with a human tutor—but without the high price or time constraints.

In a 25-minute lesson, Kylian teaches exactly what you need to know about your chosen topic: the nuances that textbooks never explain, key cultural differences between French and your target language, grammar rules, and much more.

Ever felt frustrated trying to keep up with a native-speaking teacher, or embarrassed to ask for something to be repeated? With Kylian, that problem disappears. It switches intelligently between French and the target language depending on your level, helping you understand every concept at your own pace.

During the lesson, Kylian uses role-plays, real-life examples, and adapts to your learning style. Didn’t understand something? No problem—you can pause Kylian anytime to ask for clarification, without fear of being judged.

Ask all the questions you want, repeat sections if needed, and customize your learning experience in ways traditional teachers and generic apps simply can’t match.

With 24/7 access at a fraction of the cost of private lessons, Kylian removes all the barriers that have kept you from mastering the language you’ve always wanted to learn.

Similar Content You Might Want To Read

Abbreviation for Brooklyn in English: Complete Guide

The name Brooklyn carries significant cultural and historical weight in American society. As New York City's most populous borough, Brooklyn has cultivated a distinct identity that resonates far beyond its geographical boundaries. Yet in our communication-driven age, where brevity often trumps completeness, understanding how to properly abbreviate "Brooklyn" becomes increasingly relevant—whether for postal addresses, text messages, or official documents. Why does this matter? Because clarity in communication prevents misunderstandings, saves time, and maintains professionalism. The incorrect abbreviation of location names can lead to misdirected mail, confusion in official records, and unnecessary complications in both personal and professional contexts. This comprehensive guide explores the standard and alternative abbreviations for Brooklyn, examining their proper usage across different contexts while addressing common questions about their application.

Abbreviation for Officer in English: Complete Guide

In professional and official communications, abbreviations serve as essential tools that streamline written exchanges while maintaining clarity. The abbreviation for "officer" stands among the most frequently utilized shortened forms in formal correspondence, particularly in military, law enforcement, and corporate contexts. This comprehensive guide explores the various abbreviations for "officer" across different fields, their correct usage, and the crucial considerations for employing them effectively in English communication.

![Abbreviation for Pages: Complete Guide [English]](/_next/image?url=https%3A%2F%2Fcdn.sanity.io%2Fimages%2F147z5m2d%2Fproduction%2Fddc0df01a384a4a32afaf290c8c091522d445a52-2240x1260.png%3Frect%3D175%2C0%2C1890%2C1260%26w%3D600%26h%3D400&w=3840&q=75)

Abbreviation for Pages: Complete Guide [English]

Effective written communication demands precision and clarity. Whether you're drafting academic papers, business reports, or digital content, understanding standardized abbreviations saves space and maintains professionalism. The abbreviation for "pages" stands as one of the most frequently used reference markers across multiple disciplines, yet many writers remain uncertain about its proper application. This comprehensive guide examines the correct abbreviations for "pages" across various style guides, contexts, and languages. By mastering these seemingly minor but crucial elements, you elevate your writing from adequate to exceptional, ensuring your audience focuses on your message rather than questioning your credibility.

![What is the abbreviation for yards? [English]](/_next/image?url=https%3A%2F%2Fcdn.sanity.io%2Fimages%2F147z5m2d%2Fproduction%2F4079cd1014fbfe6e6358690419279de3cf570825-2240x1260.png%3Frect%3D175%2C0%2C1890%2C1260%26w%3D600%26h%3D400&w=3840&q=75)

What is the abbreviation for yards? [English]

The standard abbreviation for yards is "yd." When measuring distances, particularly in countries using the imperial system, this two-letter abbreviation represents the unit of length equal to three feet or 36 inches. Understanding this abbreviation is essential for accurate communication in various contexts, from sports and construction to fabric purchasing and everyday measurements.

Essential Portuguese Text Slang: Acronyms & Abbreviations

Communication evolves constantly, particularly in the digital sphere where efficiency often trumps formality. Portuguese—whether spoken in Brazil, Portugal, or other Lusophone countries—has developed its own digital shorthand that proves essential for authentic conversations. Mastering Portuguese text slang represents a critical milestone in language proficiency. It bridges the gap between textbook knowledge and practical fluency, offering insights into cultural nuances that formal education rarely addresses. This guide examines the dynamic landscape of Portuguese text expressions, providing you with the tools to decode messages, participate confidently in casual conversations, and understand the cultural context behind these linguistic shortcuts.

New England Abbreviation: Different Codes & Acronyms

Understanding regional abbreviations becomes crucial when navigating business communications, official documents, or casual correspondence across America's northeastern corridor. New England's unique position as both a historical region and modern economic hub generates countless abbreviations that professionals and residents encounter daily. Whether you're relocating to Massachusetts, conducting business in Connecticut, or simply trying to decode a Vermont address, mastering these abbreviations eliminates confusion and demonstrates regional awareness. The complexity increases when you consider that New England encompasses six distinct states, each with its own governmental, educational, and cultural institutions that generate their own abbreviated forms.