Warehouse Abbreviation: Meaning & Usage Guide

Written by

Ernest Bio Bogore

Reviewed by

Ibrahim Litinine

Communication efficiency stands as a cornerstone in logistics and supply chain management. When professionals need to convey complex warehouse information quickly, abbreviations become indispensable tools. These shorthand notations streamline everything from inventory documentation to operational protocols, saving valuable time while maintaining clarity in an industry where precision matters.

The strategic deployment of warehouse abbreviations transforms potentially lengthy communications into concise messages that enhance productivity across warehouse environments. For newcomers to the field, understanding these specialized codes unlocks a critical dimension of industry communication that separates seasoned professionals from beginners.

This comprehensive guide examines the most essential warehouse abbreviations, their practical applications, and their significance in optimizing operational efficiency. Whether you're a warehouse manager, logistics specialist, or supply chain professional, mastering these abbreviated terms will elevate your communication capabilities in this fast-paced sector.

What is the Abbreviation for Warehouse?

The standard abbreviation for "warehouse" is WH. This two-letter code appears consistently across inventory management systems, shipping documentation, and logistics communications. In some contexts, especially in international shipping and enterprise resource planning systems, you might also encounter WHSE as an alternative abbreviation.

These shorthand notations serve practical purposes beyond mere convenience:

- They save character space in digital systems with text limitations

- They standardize labeling conventions across global supply chains

- They expedite documentation processes during high-volume operations

- They create uniformity in cross-departmental communications

While WH remains the most widely recognized form, industry specialization sometimes introduces variations. For instance, distribution centers might use DC, fulfillment centers might use FC, and regional warehousing facilities sometimes adopt location-specific codes like RWH (Regional Warehouse).

Understanding when to use these abbreviations appropriately requires familiarity with both industry standards and company-specific protocols, which we'll explore in detail throughout this guide.

Common Warehouse Abbreviations and Their Meanings

The warehouse environment operates with a specialized vocabulary that extends far beyond the basic WH abbreviation. These technical shorthand codes form the foundation of efficient warehouse communication across all operational areas.

Inventory Management Abbreviations

Inventory control represents one of the most abbreviation-rich aspects of warehouse operations:

- SKU (Stock Keeping Unit): Unique identifier assigned to each distinct product for inventory tracking

- UPC (Universal Product Code): Standardized barcode system for retail product identification

- EOQ (Economic Order Quantity): Optimal order quantity that minimizes total inventory costs

- FIFO (First In, First Out): Inventory valuation method where oldest items are sold first

- LIFO (Last In, First Out): Alternative inventory method where newest items are sold first

- QOH (Quantity On Hand): Current physical inventory available in the warehouse

- MOQ (Minimum Order Quantity): Smallest quantity of a product a supplier will sell

- ROP (Reorder Point): Inventory threshold that triggers new purchase orders

Warehouse Operations Abbreviations

Daily warehouse activities rely on these operational abbreviations:

- WMS (Warehouse Management System): Software controlling warehouse operations and inventory

- RF (Radio Frequency): Technology used in warehouse scanning systems

- PL (Pick List): Document listing items to be retrieved from storage

- 3PL (Third-Party Logistics): Outsourced logistics services provider

- KPI (Key Performance Indicator): Metrics used to evaluate warehouse efficiency

- SOP (Standard Operating Procedure): Documented processes for warehouse tasks

- PPE (Personal Protective Equipment): Safety gear required in warehouse environments

- VAS (Value-Added Services): Additional services beyond standard storage and shipping

Shipping and Receiving Abbreviations

The movement of goods relies heavily on these logistics abbreviations:

- PO (Purchase Order): Document authorizing a purchase transaction

- BOL (Bill of Lading): Legal document for shipping goods

- ASN (Advanced Shipping Notice): Notification sent ahead of delivery

- LTL (Less Than Truckload): Shipping method for smaller freight

- FTL (Full Truckload): Shipping method utilizing entire truck capacity

- ETA (Estimated Time of Arrival): Projected delivery time

- POD (Proof of Delivery): Documentation confirming successful delivery

- RTV (Return to Vendor): Process for sending items back to suppliers

- DG (Dangerous Goods): Hazardous materials requiring special handling

Equipment and Technology Abbreviations

Modern warehouses utilize specialized equipment represented by these abbreviations:

- MHE (Material Handling Equipment): Machinery used to move inventory

- AGV (Automated Guided Vehicle): Self-driving vehicles for material transport

- RFID (Radio Frequency Identification): Tracking technology using radio waves

- AS/RS (Automated Storage and Retrieval System): Computerized inventory management

- PLC (Programmable Logic Controller): Industrial computer controlling warehouse automation

- HMI (Human-Machine Interface): Technology allowing human interaction with warehouse systems

- VNA (Very Narrow Aisle): Specialized warehouse layout maximizing storage density

- PIT (Powered Industrial Truck): Category including forklifts and pallet jacks

Understanding these abbreviations establishes the foundation for effective warehouse communication. Each shorthand code represents a specific concept essential to warehouse operations, and their proper usage streamlines everything from documentation to verbal communication within these complex environments.

How to Use Warehouse Abbreviations Correctly

Employing warehouse abbreviations effectively requires understanding both their technical meanings and contextual applications. Improper usage can lead to costly miscommunications, operational delays, and inventory discrepancies.

Context-Specific Usage Guidelines

The appropriate abbreviation depends significantly on the communication context:

In Documentation:

- Use standardized abbreviations consistently across all written materials

- Introduce abbreviations with their full terms at first mention in longer documents

- Maintain an abbreviation glossary for reference in complex technical documentation

- Follow company style guides for approved abbreviation formats

In Digital Systems:

- Verify abbreviation compatibility with database field limitations

- Ensure abbreviation consistency across integrated software platforms

- Consider search functionality implications when implementing abbreviations

- Maintain abbreviation standards across system upgrades and migrations

In Verbal Communication:

- Confirm abbreviation familiarity among team members before relying on shorthand

- Establish clear pronunciation standards for ambiguous abbreviations

- Use full terms when communicating with external partners unfamiliar with internal codes

- Incorporate abbreviation training in onboarding processes for new employees

Common Mistakes to Avoid

Effective abbreviation usage means avoiding these frequent pitfalls:

Inconsistent Application: Using different abbreviations for the same concept across various departments creates confusion. Establish company-wide standards to ensure unified communication.

Overabbreviation: Not every term requires abbreviation. Reserve shorthand for frequently used technical terms where brevity provides genuine efficiency advantages.

Ambiguous Abbreviations: Some abbreviations carry multiple potential meanings. For example, "DC" could represent "Distribution Center" or "Direct Current." Specify meanings when abbreviations have multiple interpretations.

Outdated Terminology: Warehouse technology evolves rapidly, making some abbreviations obsolete. Regularly review abbreviation standards to reflect current operational realities.

Missing Context: Abbreviations without sufficient context can be meaningless. Ensure communications provide enough information for abbreviations to be correctly interpreted.

Industry-Specific Conventions

Different warehouse environments develop specialized abbreviation systems:

E-commerce Warehousing:

- OMS (Order Management System)

- B2C (Business to Consumer)

- CX (Customer Experience)

- DTC (Direct to Consumer)

Manufacturing Warehousing:

- WIP (Work in Progress)

- BOM (Bill of Materials)

- MRP (Material Requirements Planning)

- JIT (Just in Time)

Cold Chain Warehousing:

- CCT (Cold Chain Transport)

- TRU (Transport Refrigeration Unit)

- CCP (Critical Control Point)

- HACCP (Hazard Analysis Critical Control Point)

By adhering to these usage principles, warehouse professionals can leverage abbreviations to enhance communication efficiency while avoiding the pitfalls that lead to operational confusion.

Benefits of Using Warehouse Abbreviations

The strategic implementation of warehouse abbreviations delivers measurable advantages across multiple operational dimensions. These benefits extend beyond simple convenience to create structural efficiencies throughout warehouse environments.

Communication Efficiency

Abbreviations dramatically streamline information exchange:

- Reduced Documentation Time: Recording "WH-23-SKU-1088" rather than "Warehouse 23 Stock Keeping Unit 1088" saves approximately 75% of character space and typing time.

- Enhanced Radio Communications: Brief abbreviation codes improve clarity in noisy warehouse environments where longer phrases might be misheard.

- Expedited Training Processes: Standardized abbreviations create a common language that accelerates new employee integration into existing teams.

- International Standardization: Abbreviations often transcend language barriers, allowing multinational operations to maintain consistent communication protocols.

Technological Integration

Modern warehouse systems benefit substantially from abbreviated codes:

- Database Optimization: Abbreviated entries require less storage space and processing power, improving system performance.

- Barcode Efficiency: Shorter codes enable more compact barcodes that scan reliably even on smaller product packages.

- Mobile Application Usability: Abbreviations fit better on limited screen real estate, enhancing mobile warehouse management tools.

- API Communication: Standardized abbreviations simplify data exchange between different software systems in the warehouse technology ecosystem.

Operational Advantages

Day-to-day warehouse functions gain efficiency through proper abbreviation usage:

- Error Reduction: Well-established abbreviation standards minimize misinterpretation compared to inconsistent or ad-hoc shorthand.

- Accelerated Decision-Making: When everyone understands the same abbreviation system, operational decisions can be made more quickly with less clarification needed.

- Documentation Consistency: Standardized abbreviations ensure uniform record-keeping across shifts, departments, and facilities.

- Space Optimization: On physical labels and signage, abbreviations allow for larger, more visible text while conveying complete information.

Real-World Impact Analysis

The cumulative effect of these benefits translates to measurable business outcomes:

- Labor Efficiency: Studies indicate warehouse teams using standardized abbreviation systems complete documentation tasks up to 30% faster than those using primarily full terminology.

- Training ROI: New employees reach operational proficiency approximately 20% faster when trained with consistent abbreviation protocols.

- Error Reduction: Warehouses with formally defined abbreviation standards report approximately 45% fewer communication-related errors compared to facilities without such standards.

- Customer Satisfaction: The precision enabled by proper abbreviation usage contributes to order accuracy rates exceeding 99.5% in best-practice facilities.

These advantages demonstrate why mastering warehouse abbreviations represents more than a matter of convenience—it constitutes a fundamental operational strategy that enhances warehouse performance across multiple critical metrics.

The Evolution of Warehouse Abbreviations

The development of warehouse terminology reflects the industry's transformation from simple storage facilities to sophisticated logistics hubs. Understanding this evolution provides valuable context for current abbreviation practices.

Historical Development

Warehouse abbreviations have evolved alongside the industry itself:

Early Standardization (1950s-1970s): Initial warehouse abbreviations emerged from paper-based inventory systems where space constraints on physical forms necessitated shorthand. Basic terms like "WH" (warehouse) and "PO" (purchase order) gained widespread acceptance during this era.

Computer System Integration (1980s-1990s): The introduction of warehouse management software drove further abbreviation development. Character limits in early database systems required concise coding, establishing abbreviations like "SKU" and "UPC" as industry standards rather than mere convenience.

Global Supply Chain Expansion (2000s-2010s): International logistics growth created pressure for universally understood terminology. This period saw the standardization of shipping abbreviations like "FCL" (Full Container Load) and "LTL" (Less Than Truckload) across global supply chains.

Digital Transformation Era (2010s-Present): Modern warehouse automation has introduced entirely new abbreviation categories related to robotics ("AMR" - Autonomous Mobile Robot), IoT systems ("IIoT" - Industrial Internet of Things), and artificial intelligence applications ("ML" - Machine Learning).

Industry Standardization Efforts

Several organizations have worked to formalize warehouse terminology:

- ISO (International Organization for Standardization): Developed documentation standards including approved logistics abbreviations

- IWLA (International Warehouse Logistics Association): Promotes consistent terminology across member organizations

- CSCMP (Council of Supply Chain Management Professionals): Publishes glossaries standardizing industry abbreviations

- GS1: Establishes global standards for business communication, including many warehouse identification systems

Regional and Cultural Variations

Despite standardization efforts, notable variations persist:

North American vs. European Terminology:

- NA: "WH" (Warehouse) / EU: "DC" (Distribution Centre)

- NA: "SKU" (Stock Keeping Unit) / EU: "PLU" (Product Look-Up)

- NA: "BOL" (Bill of Lading) / EU: "CMR" (Convention on the Contract for the International Carriage of Goods by Road)

Industry-Specific Adaptations:

- Pharmaceutical: "GMP" (Good Manufacturing Practice)

- Automotive: "JIS" (Just In Sequence)

- Food: "FEFO" (First Expired, First Out)

Emerging Market Innovations: Developing regions often create hybrid abbreviation systems combining international standards with local logistics practices, particularly in rapidly growing e-commerce sectors in Asia and Latin America.

This historical perspective explains why certain abbreviations persist despite technological changes and highlights the ongoing tension between standardization needs and industry-specific adaptation in warehouse terminology.

Warehouse Abbreviations in Different Languages

While English dominates international logistics, warehouse professionals increasingly encounter abbreviations from various linguistic origins. Understanding these cross-language variations prevents costly misinterpretations in global supply chain operations.

Major Language Equivalents

Spanish Warehouse Terminology:

- English: WH (Warehouse) → Spanish: ALM (Almacén)

- English: PO (Purchase Order) → Spanish: OC (Orden de Compra)

- English: SKU (Stock Keeping Unit) → Spanish: UDI (Unidad De Inventario)

- English: QC (Quality Control) → Spanish: CC (Control de Calidad)

French Warehouse Terminology:

- English: WH (Warehouse) → French: ENT (Entrepôt)

- English: BOL (Bill of Lading) → French: LDT (Lettre de Transport)

- English: FIFO (First In, First Out) → French: PEPS (Premier Entré, Premier Sorti)

- English: PL (Picking List) → French: BP (Bon de Prélèvement)

German Warehouse Terminology:

- English: WH (Warehouse) → German: LG (Lager)

- English: PO (Purchase Order) → German: BA (Bestellauftrag)

- English: QOH (Quantity on Hand) → German: VB (Verfügbarer Bestand)

- English: ETA (Estimated Time of Arrival) → German: VAZ (Voraussichtliche Ankunftszeit)

Chinese Warehouse Terminology:

- English: WH (Warehouse) → Chinese: CK (仓库 - Cāngkù)

- English: ASN (Advanced Shipping Notice) → Chinese: YFTZT (预发通知单 - Yùfā tōngzhī dān)

- English: 3PL (Third-Party Logistics) → Chinese: DSFW (第三方物流 - Dì sān fāng wùliú)

- English: JIT (Just In Time) → Chinese: ZSD (准时达 - Zhǔnshí dá)

Multilingual Documentation Challenges

Global supply chains face several abbreviation-related challenges:

Homograph Conflicts: Same abbreviations with different meanings across languages can cause confusion. For example, "BL" represents "Bill of Lading" in English but "Bon de Livraison" (delivery note) in French.

Character Set Limitations: Many warehouse management systems cannot properly display non-Latin characters, forcing transliteration of abbreviations from languages like Chinese, Arabic, or Russian.

Regulatory Compliance: Some countries require documentation in local languages with specific approved terminology, creating parallel abbreviation systems for regulatory versus operational purposes.

Best Practices for International Warehouse Communication

Organizations operating across language boundaries should implement these strategies:

Standardized Abbreviation Dictionaries: Develop comprehensive cross-reference materials listing equivalent abbreviations across all operational languages.

Visual Communication Systems: Implement icon-based labeling that transcends language barriers, particularly for safety-related information.

Default Language Protocols: Establish clear rules for which language takes precedence in specific documentation contexts.

Training for Language-Specific Nuances: Provide specialized training for staff working with abbreviations across multiple languages.

Translation Technology Integration: Implement systems that automatically convert abbreviations between languages in digital warehouse documentation.

Understanding these linguistic variations becomes increasingly important as supply chains continue to globalize, with effective multilingual abbreviation management becoming a competitive advantage for international warehouse operations.

Warehouse Abbreviations in Digital Documentation

The transition to digital warehouse management has transformed how abbreviations function within information systems. Modern documentation practices must balance abbreviation efficiency with digital searchability, integration requirements, and data governance.

Warehouse Management Systems (WMS)

WMS platforms handle abbreviations according to specific technical parameters:

Database Field Considerations:

- Field length limitations often necessitate abbreviation usage

- Consistent abbreviation formatting prevents database fragmentation

- Some systems maintain separate fields for abbreviated and full-form data

- Query optimization requires standardized abbreviation structures

Cross-Platform Integration:

- API connections between systems may require abbreviation mapping tables

- EDI (Electronic Data Interchange) standards specify acceptable abbreviations

- Cloud-based WMS solutions often enforce global abbreviation standards

- Legacy system integration frequently requires abbreviation translation protocols

Search Functionality Impact:

- Advanced systems support abbreviation recognition in search algorithms

- Synonym dictionaries connect abbreviated and full terms

- Some platforms implement fuzzy matching for abbreviation variations

- Search indexing treats abbreviations differently from standard text

Electronic Documentation Standards

Various electronic document formats handle abbreviations differently:

EDI Document Types:

- ASN (Advanced Shipping Notice): Uses highly standardized abbreviation codes

- 940 (Warehouse Shipping Order): Employs location and item abbreviations

- 944 (Warehouse Stock Transfer Receipt): Contains specialized inventory abbreviations

- 856 (Ship Notice/Manifest): Includes carrier and routing abbreviations

PDF Documentation:

- Searchable PDFs should include abbreviation metadata

- PDF form fields often enforce abbreviation consistency

- Bookmarking and indexing systems typically use abbreviated codes

- Digital signature blocks frequently include role abbreviations

Mobile and IoT Application Considerations

Emerging technologies introduce new abbreviation requirements:

Mobile Warehouse Applications:

- Screen size limitations increase abbreviation necessity

- Voice-directed picking systems must recognize spoken abbreviations

- Mobile interface design typically relies on icon-abbreviation combinations

- Barcode scanning apps often display abbreviated feedback confirmations

IoT Sensor Data:

- Data transmission efficiency requires highly abbreviated formats

- Sensor identification systems use location and function abbreviations

- Real-time monitoring dashboards display abbreviated status indicators

- Alert systems employ standardized abbreviation codes for various conditions

Wearable Technology:

- Smart glasses display abbreviated instructions and confirmations

- Wearable scanners use minimal text with maximum abbreviation

- Haptic feedback systems correspond to abbreviated command sets

- Voice recognition systems must distinguish between similar-sounding abbreviations

The digital transformation of warehouse operations continues to reshape abbreviation practices, with emerging technologies consistently driving new shorthand development while simultaneously requiring greater standardization across interconnected systems.

Learning and Memorizing Warehouse Abbreviations

Mastering warehouse abbreviations represents a significant professional development challenge for industry newcomers. Effective learning strategies can accelerate this process while ensuring long-term retention.

Systematic Learning Approaches

Structured methodologies prove most effective for abbreviation acquisition:

Categorical Organization: Rather than attempting to memorize abbreviations alphabetically, group them by functional category:

- Inventory abbreviations (SKU, UPC, EOQ)

- Shipping abbreviations (BOL, LTL, FCL)

- Equipment abbreviations (MHE, AGV, PIT)

This approach creates meaningful associations between related terms, enhancing recall in practical situations.

Progressive Learning Sequence: Begin with the most frequently used abbreviations before advancing to specialized terminology:

- Start with universal basics (WH, PO, SKU)

- Add role-specific terminology based on job function

- Incorporate industry-specific variations

- Master cross-departmental abbreviations

Contextual Learning: Integrate abbreviation learning with operational processes:

- Study pick lists while learning picking abbreviations

- Review shipping documentation while mastering logistics abbreviations

- Examine inventory reports when learning stock management abbreviations

Memorization Techniques

Cognitive science offers several proven methods for abbreviation retention:

Mnemonic Devices: Create memory aids connecting abbreviations to their meanings:

- "WMS manages Where My Stuff is located"

- "FIFO means the First Items are the First Out"

- "3PL reminds us that Three Parties handle the Logistics"

Spaced Repetition: Review abbreviations at increasingly longer intervals:

- Initial learning

- Review after 1 day

- Review after 3 days

- Review after 1 week

- Review after 2 weeks

Research shows this approach optimizes long-term retention compared to intensive cramming sessions.

Visualization Methods: Associate abbreviations with mental images:

- Imagine a physical SKU label when recalling "SKU"

- Visualize items being picked from shelves when remembering "PL"

- Picture trucks arriving at loading docks when working with "ETA"

Resources for Abbreviation Mastery

Several tools facilitate systematic abbreviation learning:

Digital Flashcard Systems: Applications like Anki or Quizlet allow creation of warehouse-specific flashcard decks with spaced repetition algorithms.

Reference Materials:

- Industry association glossaries

- Company-specific abbreviation dictionaries

- Department-specific quick reference guides

- Visual warehouse maps with abbreviation codes

Interactive Learning Tools:

- Warehouse simulation software

- Documentation practice systems

- Abbreviation recognition games

- Virtual warehouse tours with abbreviation identification

Organizations that implement structured abbreviation training programs report significantly faster employee onboarding and higher accuracy rates in documentation processes, demonstrating the tangible operational value of systematic abbreviation education.

Creating Your Own Warehouse Abbreviation System

While industry standards provide a foundation, many organizations develop customized abbreviation systems to address their specific operational needs. A well-designed proprietary abbreviation framework can enhance efficiency while maintaining clarity.

Design Principles for Effective Systems

Successful warehouse abbreviation systems adhere to these fundamental principles:

Consistency:

- Establish uniform abbreviation patterns (e.g., always using 3 letters)

- Apply consistent capitalization conventions

- Maintain structural parallelism across related terms

- Document standards in a formal style guide

Intuitiveness:

- Select abbreviations that logically connect to their full terms

- Avoid ambiguous shortenings that could have multiple interpretations

- Consider phonetic relationships between terms and their abbreviations

- Test abbreviation recognition with diverse warehouse staff

Scalability:

- Design systems that accommodate future terminology expansion

- Create logical category structures with room for growth

- Implement version control for abbreviation standards

- Establish formal processes for abbreviation updates

Compatibility:

- Align custom abbreviations with industry standards where possible

- Ensure abbreviations work within technology system constraints

- Verify abbreviation functionality across all documentation formats

- Test integration with partner and vendor systems

Implementation Strategy

Developing and deploying a custom abbreviation system requires methodical execution:

Analysis Phase:

- Audit existing abbreviation usage across all warehouse functions

- Identify standardization opportunities and problem areas

- Benchmark against industry best practices

- Document specific organizational requirements

Development Phase:

- Create initial abbreviation standards with stakeholder input

- Test draft standards with representative user groups

- Refine based on usability feedback

- Formalize standards in official documentation

Deployment Phase:

- Develop comprehensive training materials

- Implement graduated rollout starting with pilot departments

- Provide reference resources at point of use

- Establish feedback mechanisms for continuous improvement

Maintenance Phase:

- Schedule regular review of abbreviation effectiveness

- Document exceptions and special cases

- Update standards based on operational changes

- Integrate new terminology as technologies evolve

Case Study: Building a Location-Based Abbreviation System

Consider this example of a comprehensive warehouse location abbreviation framework:

Zone Designations:

- RCV (Receiving)

- PKG (Picking)

- SHP (Shipping)

- BLK (Bulk Storage)

- HVA (High-Value Area)

Aisle Identification:

- Format: [Zone]-[Aisle Number]-[Section]

- Example: PKG-04-C (Picking Area, Aisle 4, Section C)

Bin Locators:

- Format: [Zone]-[Aisle]-[Bay]-[Level]-[Position]

- Example: BLK-12-03-02-04 (Bulk Storage, Aisle 12, Bay 3, Level 2, Position 4)

Special Location Codes:

- QC-1 (Quality Control Station 1)

- VAS-B (Value-Added Services Area B)

- RWK-3 (Rework Station 3)

This systematic approach creates a complete location abbreviation framework that workers can quickly learn and apply, while providing sufficient detail for precise inventory location.

Organizations that invest in thoughtfully designed proprietary abbreviation systems often realize significant efficiency gains, particularly in complex multi-facility operations where standardization delivers substantial operational advantages.

Future Trends in Warehouse Abbreviation Usage

The evolution of warehouse technology and operational models continues to reshape abbreviation systems. Forward-thinking logistics professionals should anticipate these emerging trends that will influence future warehouse terminology.

Technology-Driven Abbreviation Evolution

Advanced technologies are introducing entirely new abbreviation categories:

Artificial Intelligence Integration:

- ANN (Artificial Neural Network)

- NLP (Natural Language Processing)

- PDA (Predictive Demand Analytics)

- AIPF (AI-Powered Forecasting)

Robotics and Automation:

- CPS (Cyber-Physical Systems)

- RVC (Robot Vision Controller)

- ASP (Automated Slotting Protocols)

- DLT (Digital Location Tracking)

Augmented Reality Applications:

- ARD (Augmented Reality Display)

- VSP (Visual Picking System)

- MRW (Mixed Reality Warehouse)

- SLO (Spatial Location Overlay)

Internet of Things Expansion:

- RTLS (Real-Time Location System)

- EIOT (Edge Internet of Things)

- WSN (Wireless Sensor Network)

- DTM (Digital Twin Modeling)

Changing Operational Models

Evolving business paradigms are creating new abbreviation requirements:

Omnichannel Fulfillment:

- OFC (Omnichannel Fulfillment Center)

- SFS (Ship From Store)

- BSP (Buy-Ship-Pickup)

- LMD (Last Mile Delivery)

Sustainable Operations:

- EPM (Environmental Performance Metrics)

- CSC (Carbon Supply Chain)

- EIR (Environmental Impact Reduction)

- SLM (Sustainable Logistics Management)

Micro-Fulfillment Models:

- MFC (Micro-Fulfillment Center)

- UDC (Urban Distribution Center)

- DFC (Dark Fulfillment Center)

- HDD (Hyper-Local Delivery Distribution)

Resilience-Focused Operations:

- BCP (Business Continuity Planning)

- SRW (Supply Risk Weighting)

- RAM (Resilience Assessment Matrix)

- DCR (Disruption Capacity Rating)

Standardization and Regulation Impacts

External forces continue to shape abbreviation development:

Regulatory Harmonization: Global logistics regulators are increasingly coordinating terminology standards, likely leading to more universally accepted abbreviations, particularly in:

- Hazardous materials handling

- Cross-border documentation

- Product identification systems

- Labor safety protocols

Industry Association Initiatives: Organizations like the Warehouse Education and Research Council (WERC) are developing more comprehensive abbreviation standards to support workforce mobility and system interoperability.

Technology Vendor Ecosystems: Major WMS and supply chain technology providers are creating proprietary abbreviation systems that may become de facto standards through market dominance.

International Trade Developments: Changing trade relationships will necessitate new documentation approaches with corresponding abbreviation systems, particularly for:

- Rules of origin certification

- Sustainability documentation

- Ethical sourcing verification

- Regional trade agreement compliance

Anticipating Future Needs

Organizations can prepare for these trends by:

- Designing abbreviation systems with flexibility for emerging technologies

- Building abbreviation databases with cross-reference capabilities

- Implementing regular terminology review processes

- Participating in industry standardization initiatives

- Incorporating abbreviation future-proofing in technology procurement decisions

The warehouse sector's increasingly rapid evolution suggests abbreviation systems will continue to expand and transform. Organizations that approach terminology management strategically rather than reactively will maintain communication efficiency even as operational models undergo fundamental changes.

Learn Any Language with Kylian AI

Private language lessons are expensive. Paying between 15 and 50 euros per lesson isn’t realistic for most people—especially when dozens of sessions are needed to see real progress.

Many learners give up on language learning due to these high costs, missing out on valuable professional and personal opportunities.

That’s why we created Kylian: to make language learning accessible to everyone and help people master a foreign language without breaking the bank.

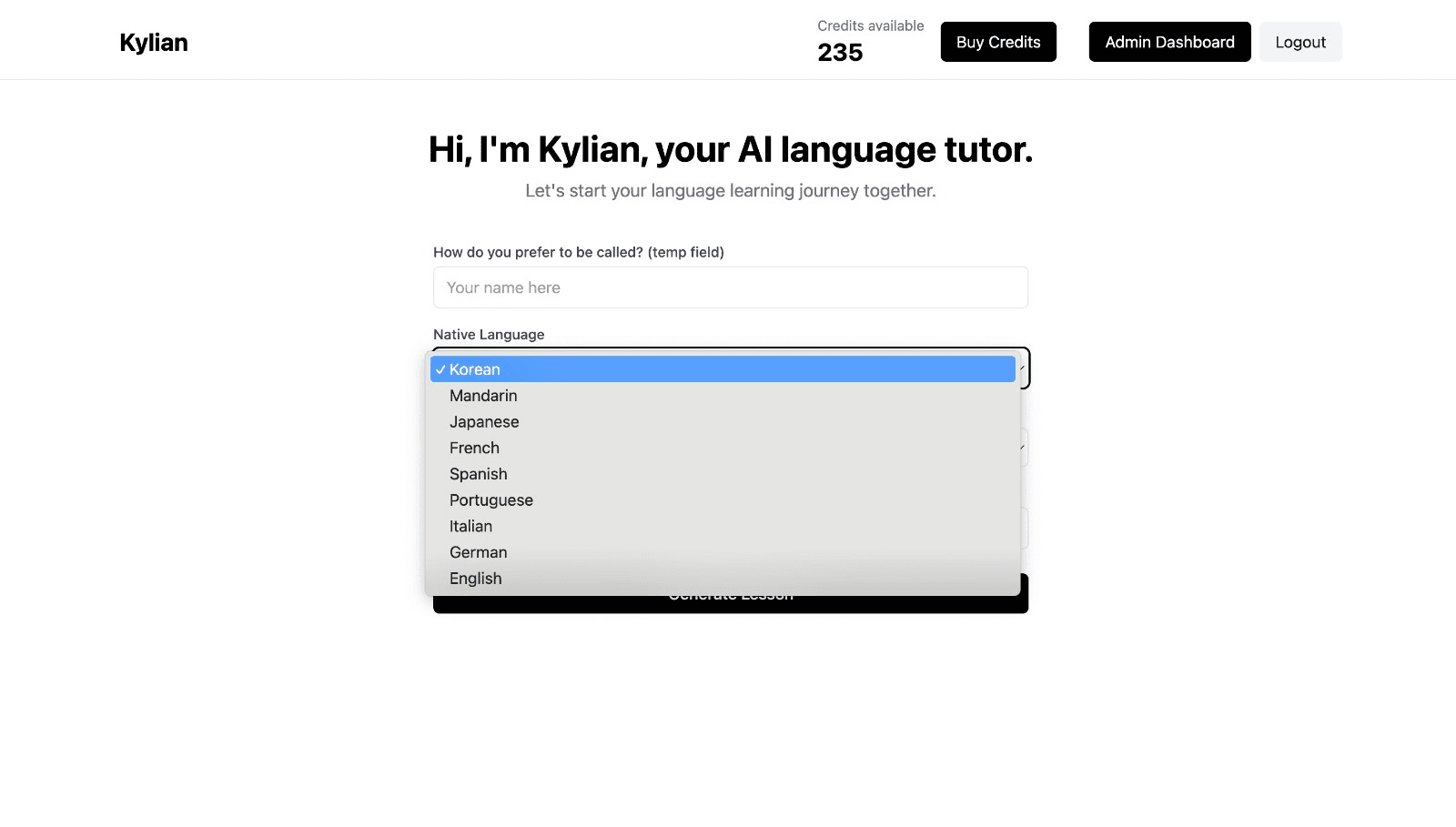

To get started, just tell Kylian which language you want to learn and what your native language is

Tired of teachers who don’t understand your specific struggles as a French speaker? Kylian’s advantage lies in its ability to teach any language using your native tongue as the foundation.

Unlike generic apps that offer the same content to everyone, Kylian explains concepts in your native language (French) and switches to the target language when necessary—perfectly adapting to your level and needs.

This personalization removes the frustration and confusion that are so common in traditional language learning.

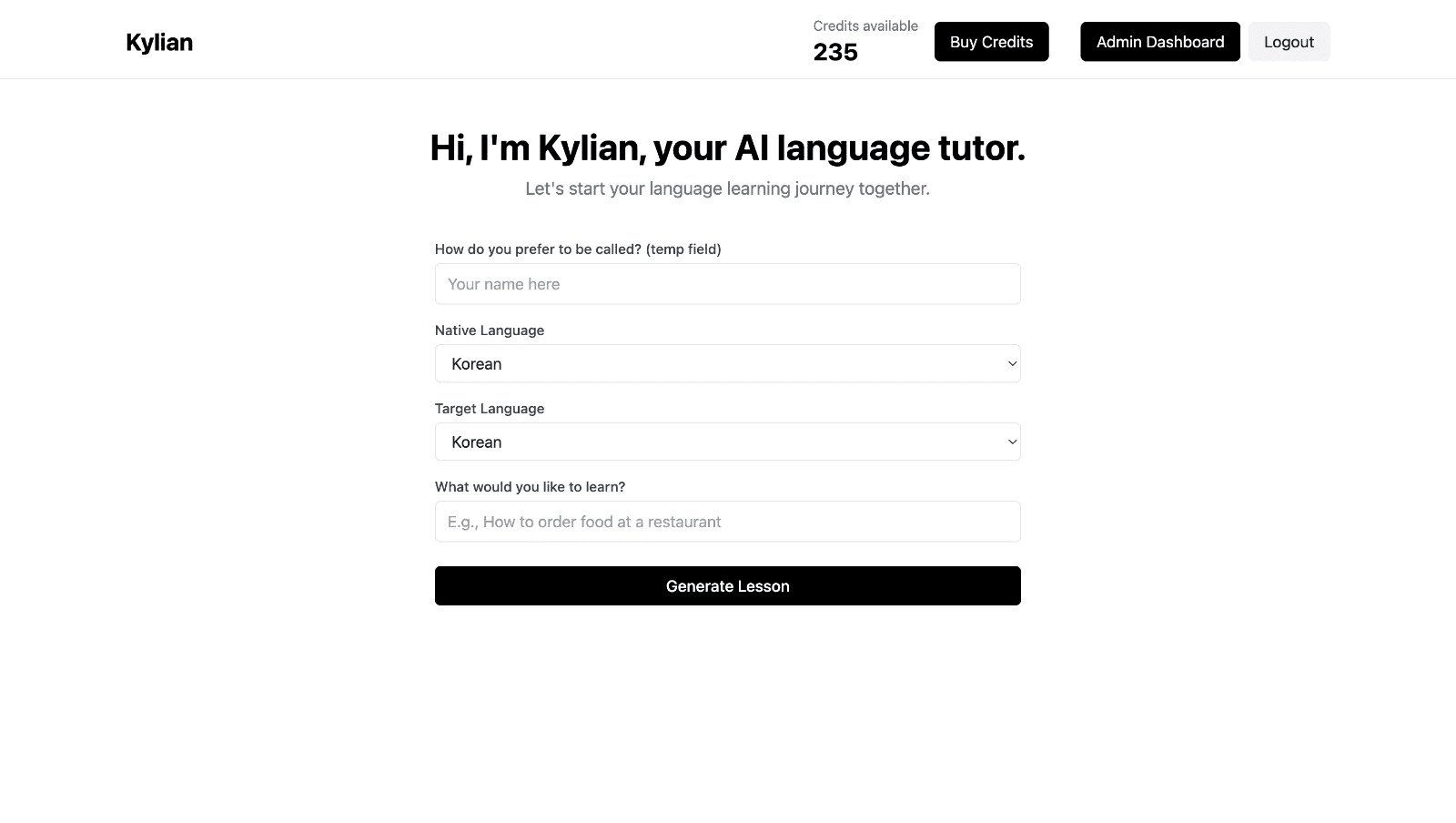

Choose a specific topic you want to learn

Frustrated by language lessons that never cover exactly what you need? Kylian can teach you any aspect of a language—from pronunciation to advanced grammar—by focusing on your specific goals.

Avoid vague requests like “How can I improve my accent?” and be precise: “How do I pronounce the R like a native English speaker?” or “How do I conjugate the verb ‘to be’ in the present tense?”

With Kylian, you’ll never again pay for irrelevant content or feel embarrassed asking “too basic” questions to a teacher. Your learning plan is entirely personalized.

Once you’ve chosen your topic, just hit the “Generate a Lesson” button, and within seconds, you’ll get a lesson designed exclusively for you.

Join the room to begin your lesson

The session feels like a one-on-one language class with a human tutor—but without the high price or time constraints.

In a 25-minute lesson, Kylian teaches exactly what you need to know about your chosen topic: the nuances that textbooks never explain, key cultural differences between French and your target language, grammar rules, and much more.

Ever felt frustrated trying to keep up with a native-speaking teacher, or embarrassed to ask for something to be repeated? With Kylian, that problem disappears. It switches intelligently between French and the target language depending on your level, helping you understand every concept at your own pace.

During the lesson, Kylian uses role-plays, real-life examples, and adapts to your learning style. Didn’t understand something? No problem—you can pause Kylian anytime to ask for clarification, without fear of being judged.

Ask all the questions you want, repeat sections if needed, and customize your learning experience in ways traditional teachers and generic apps simply can’t match.

With 24/7 access at a fraction of the cost of private lessons, Kylian removes all the barriers that have kept you from mastering the language you’ve always wanted to learn.

Similar Content You Might Want To Read

Master German Dog Commands: A Guide for Dog Owners

German dog training commands have earned their reputation in the canine world for their clarity and effectiveness. The sharp, distinct sounds of German commands cut through ambient noise, creating unmistakable signals that dogs quickly learn to recognize. This comprehensive guide explores why German commands are preferred by professional trainers worldwide and provides you with practical vocabulary to implement with your own canine companion.

How to Say Thank You in Chinese (and Pronounce it Correctly)

In the vast landscape of global languages, Mandarin Chinese stands as the most widely spoken language in the world. With over a billion speakers, learning even basic phrases can open doors to meaningful connections across cultural boundaries. Among these essential expressions, "thank you" holds particular significance—it's often the first phrase travelers and language learners seek to master. This article delves into the nuanced art of expressing gratitude in Chinese. We'll examine the various forms of "thank you," explore their correct pronunciations with audio guidance, and uncover the cultural dimensions that give these expressions their true meaning. Understanding gratitude in Chinese extends beyond memorizing words; it's about grasping cultural context and embodying respect.

How Long Does It Take to Learn Japanese? Real Timelines

Curious about mastering Japanese? Whether you're planning a trip to Tokyo, hoping to understand your favorite anime without subtitles, or aiming to enhance your career prospects, one question inevitably arises: how long does it take to become fluent in Japanese? This comprehensive guide offers tailored timelines for various learning styles and objectives – crucial factors that influence your progress – plus expert strategies to accelerate your Japanese language acquisition.

How to Say Goodbye in Italian: The Complete Guide

In 1968, Italian singer Caterina Caselli captured the essence of an Italian farewell with her hit song "Arrivederci amore, ciao." Whether you're ending a relationship or simply parting ways after a coffee with friends, knowing how to say goodbye in Italian is essential to mastering the language and culture. This comprehensive guide covers everything you need to know about Italian farewells - from casual to formal, spoken to written. You'll discover the perfect expression for every situation and learn the cultural nuances that will help you sound like a native speaker.

Master Any Language Fast with Olly Richards: Polyglot Tips

Learning a new language often feels like climbing an insurmountable mountain. The grammar rules, vocabulary lists, and pronunciation challenges can be overwhelming. But what if there were proven methods to accelerate this process? Polyglot Olly Richards, who speaks eight languages (French, Spanish, Portuguese, Japanese, Thai, Arabic, Cantonese, and Italian), offers valuable insights on rapid language acquisition. Richards has developed the StoryLearning® method and has demonstrated the ability to become conversational in a language in just 90 days—an impressive feat he accomplished with Italian. Let's explore the scientifically-backed strategies and practical advice from someone who has repeatedly navigated the language learning journey successfully.

Top 10 ASL Apps to Master Sign Language (2025)

Finding the right tool to learn American Sign Language can transform your journey from frustrating to fulfilling. After rigorous testing and analysis, I've identified the most effective ASL learning applications available today, evaluating their methodologies, features, and value propositions. This research-backed guide cuts through marketing claims to present options that genuinely advance your signing skills, whether you're a complete beginner or looking to refine existing abilities.