Abbreviation for Maintenance: Key Terms & Shortcuts

Written by

Ernest Bio Bogore

Reviewed by

Ibrahim Litinine

Equipment breaks down. Systems fail. Assets deteriorate. These realities drive a $647 billion global maintenance industry where precise communication can mean the difference between scheduled downtime and catastrophic failure.

Professional maintenance environments demand speed and accuracy in documentation, work orders, and communication protocols. Understanding standard abbreviations becomes critical when technicians need to decode maintenance logs, prioritize repair schedules, or communicate urgency levels across departments.

In this article, we'll decode the essential abbreviations that maintenance professionals use daily, from basic repair codes to advanced predictive maintenance terminology.

Essential Everyday Maintenance Abbreviations

The foundation of maintenance communication rests on standardized abbreviations that appear across industries. These core terms streamline documentation and ensure consistent interpretation regardless of facility type or organizational structure.

MAINT serves as the universal abbreviation for maintenance itself, appearing in everything from budget line items to software system labels. Most computerized maintenance management systems (CMMS) default to this four-letter designation because it maintains clarity while conserving character space in database fields.

PM represents preventive maintenance, the systematic approach that reduces equipment failure rates by 12-18% according to industrial reliability studies. This abbreviation appears frequently in scheduling software and work order systems where technicians distinguish between reactive repairs and planned interventions.

CM denotes corrective maintenance, the responsive actions taken after equipment failure occurs. Unlike preventive measures, corrective maintenance addresses immediate problems and typically carries higher labor costs due to urgency requirements and potential secondary damage.

WO stands for work order, the fundamental documentation unit that tracks maintenance activities from initiation through completion. Modern facilities process thousands of work orders annually, making this abbreviation essential for efficient record-keeping and regulatory compliance.

The context surrounding these abbreviations significantly influences their application and interpretation. Manufacturing environments prioritize speed and standardization, leading to more aggressive abbreviation usage in verbal communication and documentation systems. Healthcare facilities emphasize precision and regulatory compliance, resulting in more conservative abbreviation practices with detailed explanations accompanying shortened terms.

Consider how "MAINT SCHED" might appear in a manufacturing plant's daily briefing versus "Maintenance Schedule" in a hospital's compliance documentation. Both convey identical information, but regulatory requirements and operational urgency dictate the appropriate level of formality.

Maintenance Type Classifications and Their Abbreviations

Maintenance strategies have evolved beyond simple repair-versus-replace decisions. Modern facilities implement sophisticated approaches that require precise terminology to differentiate methodologies, priorities, and resource allocation strategies.

The selection of appropriate maintenance abbreviations depends heavily on several operational factors that influence communication effectiveness and safety outcomes:

- Industry regulatory requirements that mandate specific documentation standards

- Organizational hierarchy levels where abbreviations may confuse non-technical stakeholders

- Emergency response protocols requiring immediate comprehension without interpretation delays

- International workforce considerations where abbreviation meanings may vary across cultures

- Technology integration needs matching human-readable codes with software system requirements

PdM represents predictive maintenance, the data-driven approach that analyzes equipment conditions to forecast failure probabilities. This methodology reduces maintenance costs by 25-30% while extending asset lifecycles through optimized intervention timing. Predictive maintenance programs rely heavily on sensor data, vibration analysis, and thermal imaging to identify deterioration patterns before critical failures occur.

CBM indicates condition-based maintenance, where interventions trigger based on actual equipment conditions rather than predetermined schedules. Unlike predictive approaches that forecast future states, condition-based maintenance responds to current performance indicators and operational parameters.

RCM stands for reliability-centered maintenance, a systematic methodology that determines optimal maintenance strategies based on failure mode analysis and consequence evaluation. Organizations implementing RCM report 20-35% reductions in maintenance costs while improving equipment availability and safety performance.

TPM represents total productive maintenance, the comprehensive approach that engages operators in routine maintenance activities while emphasizing continuous improvement and waste elimination. This Japanese-originated methodology transforms maintenance from a cost center into a value-generating organizational capability.

Emergency Response and Priority Maintenance Abbreviations

Critical situations demand immediate recognition and response, making standardized emergency abbreviations essential for safety and operational continuity. These designations communicate urgency levels and required response protocols without ambiguity or interpretation delays.

EMER designates emergency maintenance situations requiring immediate response regardless of scheduling conflicts or resource constraints. Emergency classifications typically involve safety hazards, environmental risks, or production-critical equipment failures that threaten organizational operations or personnel welfare.

URG represents urgent maintenance requests that require same-day attention but don't pose immediate safety risks. Urgent classifications balance operational needs with resource availability, allowing maintenance teams to prioritize effectively while maintaining safety standards.

CRIT indicates critical maintenance activities that affect primary production processes or essential safety systems. Critical designations often involve equipment supporting regulatory compliance, environmental protection, or core business functions that cannot operate without specific assets.

STAT borrowed from medical terminology, indicates immediate action requirements in maintenance contexts. This abbreviation appears frequently in industries where downtime costs exceed $50,000 per hour, making rapid response economically justified despite premium labor rates.

Emergency response protocols vary significantly across industries, with chemical processing facilities requiring 15-minute response times for critical alarms while office buildings may allow 4-hour windows for urgent requests. Understanding these contextual differences prevents miscommunication and ensures appropriate resource allocation during crisis situations.

Scheduled Maintenance and Planning Abbreviations

Effective maintenance planning requires sophisticated scheduling systems that balance resource availability, operational requirements, and regulatory compliance deadlines. Planning abbreviations streamline communication between maintenance teams, operations personnel, and management stakeholders.

SCHED represents scheduled maintenance activities planned in advance with confirmed resource allocation and operational coordination. Scheduled maintenance typically achieves 15-20% better cost efficiency compared to reactive approaches due to optimized parts procurement, labor scheduling, and operational downtime coordination.

PLAN indicates maintenance activities in planning stages where resource requirements, timing, and execution strategies undergo development. Planning phases often consume 30-40% of total maintenance labor hours in complex facilities where coordination requirements span multiple departments and external contractors.

BACKLOG refers to approved maintenance work awaiting resource availability or scheduling confirmation. Effective maintenance organizations maintain 2-4 weeks of backlog to ensure continuous productivity while avoiding resource overcapacity during peak demand periods.

OUTAGE designates planned shutdown periods where major maintenance activities occur on equipment that cannot be serviced during normal operations. Outage planning requires months of preparation and typically involves coordination between maintenance teams, operations personnel, contractors, and regulatory agencies.

The complexity of modern maintenance scheduling demands integration between computerized systems and human decision-making processes. Advanced planning systems now incorporate weather forecasts, production schedules, labor availability, parts procurement lead times, and regulatory inspection requirements into optimization algorithms that maximize asset availability while minimizing total ownership costs.

Technical Documentation and Compliance Abbreviations

Regulatory compliance and technical documentation requirements generate substantial abbreviation usage in maintenance environments. These designations ensure consistent interpretation across audits, inspections, and legal proceedings while streamlining routine documentation processes.

SOP stands for standard operating procedure, the detailed instructions governing maintenance activities to ensure consistent execution and regulatory compliance. Organizations with comprehensive SOP libraries report 25-40% fewer maintenance-related incidents and significantly improved audit performance compared to facilities relying on informal procedures.

QC represents quality control, the verification processes that confirm maintenance work meets specified standards and regulatory requirements. Quality control activities typically consume 8-12% of total maintenance labor hours but prevent costly rework and regulatory violations that could result in facility shutdowns or penalty assessments.

INSP indicates inspection activities that assess equipment conditions, regulatory compliance, and maintenance effectiveness. Inspection programs serve dual purposes by identifying emerging problems before they become failures while demonstrating regulatory compliance to auditing agencies.

CERT designates certification requirements for personnel, equipment, or procedures that must meet specific regulatory or industry standards. Certification tracking becomes critical in highly regulated industries where non-compliance can result in operational shutdowns, financial penalties, or criminal liability.

DOC represents documentation requirements that support regulatory compliance, warranty claims, insurance coverage, and legal proceedings. Modern maintenance organizations generate substantial documentation volumes, with large facilities producing 50,000+ pages annually of maintenance records, inspection reports, and compliance certifications.

Asset Management and Inventory Abbreviations

Effective maintenance depends on sophisticated asset management and inventory control systems that track equipment conditions, parts availability, and lifecycle costs. These abbreviations facilitate communication between maintenance teams, procurement personnel, and financial stakeholders.

EAM stands for enterprise asset management, comprehensive software systems that integrate maintenance planning, inventory control, financial tracking, and regulatory compliance into unified platforms. Organizations implementing EAM systems report 20-30% improvements in maintenance efficiency while reducing inventory carrying costs through optimized procurement strategies.

CMMS represents computerized maintenance management systems, specialized software that manages work orders, preventive maintenance schedules, inventory tracking, and performance reporting. Modern CMMS platforms process millions of transactions annually in large facilities while providing real-time visibility into maintenance operations and costs.

BOM indicates bill of materials, detailed parts lists required for specific maintenance activities or equipment repairs. Accurate BOM management prevents project delays caused by parts shortages while optimizing inventory investments through consolidated procurement strategies.

MRO stands for maintenance, repair, and operations, the category encompassing all materials consumed in maintenance activities except direct production inputs. MRO spending typically represents 5-15% of total manufacturing costs, making effective procurement and inventory management critical for organizational profitability.

MTBF represents mean time between failures, the statistical measure indicating average operational periods between equipment breakdowns. MTBF calculations guide preventive maintenance scheduling, spare parts inventory levels, and equipment replacement decisions based on reliability performance trends.

Digital Maintenance and Technology Abbreviations

Technology transformation revolutionizes maintenance practices through sensors, analytics, artificial intelligence, and mobile platforms. These digital abbreviations reflect evolving capabilities that enhance maintenance effectiveness while reducing costs and improving safety outcomes.

IoT indicates Internet of Things, networked sensors and devices that provide real-time equipment monitoring and automated data collection. IoT implementations in maintenance environments reduce manual inspection labor by 40-60% while improving failure detection accuracy through continuous monitoring capabilities.

RFID stands for radio frequency identification, tagging technology that automates asset tracking, parts management, and personnel access control. RFID systems eliminate manual data entry errors while providing real-time visibility into equipment locations, maintenance histories, and inventory transactions.

AR represents augmented reality, technology platforms that overlay digital information onto physical environments through mobile devices or specialized equipment. AR applications in maintenance reduce training time by 35-50% while improving first-time fix rates through enhanced troubleshooting guidance and documentation access.

ML indicates machine learning, artificial intelligence approaches that analyze historical data patterns to optimize maintenance decisions and predict equipment failures. Machine learning algorithms process millions of data points to identify subtle patterns that human analysis cannot detect, enabling more precise maintenance timing and resource allocation.

API stands for application programming interface, software connections that enable data sharing between different maintenance systems and platforms. API integration eliminates manual data transfer while ensuring consistent information across enterprise systems, reducing errors and improving decision-making speed.

International Standards and Certification Abbreviations

Global maintenance practices increasingly align with international standards that ensure consistency, safety, and interoperability across organizations and borders. These abbreviations appear in certification requirements, audit documentation, and professional development programs.

ISO represents International Organization for Standardization, the global body establishing maintenance standards including ISO 55000 for asset management and ISO 14224 for reliability data collection. ISO compliance demonstrates organizational commitment to best practices while facilitating international business relationships and regulatory acceptance.

API in this context stands for American Petroleum Institute, which develops maintenance standards widely adopted across energy and chemical processing industries. API standards influence maintenance practices in refineries, petrochemical plants, and pipeline operations where safety and environmental protection requirements exceed typical industrial applications.

ASME indicates American Society of Mechanical Engineers, professional organization establishing codes and standards for pressure vessels, boilers, and mechanical systems requiring specialized maintenance approaches. ASME compliance becomes mandatory for equipment operating under specific pressure and temperature conditions.

OSHA represents Occupational Safety and Health Administration, regulatory agency establishing workplace safety requirements that significantly influence maintenance procedures and documentation practices. OSHA compliance requires detailed documentation of maintenance activities involving hazardous materials, confined spaces, and electrical systems.

Cultural Nuances in Maintenance Communication

Professional maintenance environments span diverse cultural contexts where abbreviation usage patterns reflect organizational values, communication styles, and operational priorities. Understanding these cultural dimensions prevents miscommunication while improving collaboration effectiveness across international teams and multi-site organizations.

American maintenance culture emphasizes efficiency and standardization, leading to aggressive abbreviation adoption in verbal communication and documentation systems. This approach prioritizes speed and consistency but may sacrifice clarity when communicating with international partners or non-technical stakeholders unfamiliar with industry-specific terminology.

European maintenance practices tend toward more conservative abbreviation usage with greater emphasis on detailed documentation and regulatory compliance. This cultural preference reflects stronger regulatory environments and liability concerns that prioritize precision over communication efficiency, particularly in industries involving public safety or environmental protection.

Asian maintenance cultures often blend traditional hierarchical communication patterns with modern technical abbreviations, creating hybrid approaches that respect organizational authority while embracing operational efficiency. These cultural considerations become critical when implementing global maintenance standards across organizations with diverse workforce compositions.

Advanced Maintenance Strategy Abbreviations

Sophisticated maintenance organizations implement complex strategies that require specialized abbreviations to differentiate methodologies, measure performance, and communicate strategic decisions across organizational levels.

RCA stands for root cause analysis, systematic investigation methods that identify fundamental failure causes rather than addressing symptoms. Effective RCA programs reduce recurring failures by 60-80% while improving long-term equipment reliability through targeted interventions addressing underlying problems.

FMEA represents failure mode and effects analysis, proactive methodology that evaluates potential failure modes and their consequences before they occur. FMEA applications in maintenance planning identify critical failure points while optimizing preventive maintenance strategies based on risk assessment rather than traditional time-based approaches.

KPI indicates key performance indicators, quantitative measures that evaluate maintenance effectiveness and organizational performance. Common maintenance KPIs include overall equipment effectiveness (OEE), maintenance cost per unit produced, and planned maintenance percentage, providing objective performance measurement for continuous improvement initiatives.

OEE stands for overall equipment effectiveness, comprehensive metric combining availability, performance, and quality measures into single performance indicators. World-class manufacturing facilities achieve OEE scores above 85%, while average facilities typically operate between 60-70%, indicating substantial improvement opportunities through enhanced maintenance practices.

Professional Development and Training Abbreviations

Maintenance professionals require continuous learning and certification to maintain competency with evolving technologies, regulations, and best practices. These abbreviations appear in training programs, certification requirements, and professional development documentation.

CPD represents continuing professional development, ongoing education requirements that maintain professional certifications and ensure current knowledge of industry developments. CPD requirements typically mandate 20-40 hours annually of verified training activities covering technical skills, safety procedures, and regulatory updates.

CRL stands for certified reliability leader, professional designation recognizing expertise in reliability engineering and maintenance optimization. CRL certification requires demonstrated experience, comprehensive examination, and ongoing education commitments that validate advanced competency in maintenance strategy development and implementation.

CMRP indicates certified maintenance and reliability professional, credential recognizing comprehensive knowledge across maintenance and reliability disciplines. CMRP certification demonstrates mastery of preventive maintenance, predictive technologies, root cause analysis, and maintenance planning methodologies essential for senior maintenance roles.

SME represents subject matter expert, designation for individuals with specialized knowledge in specific maintenance areas or technologies. SME identification becomes critical for complex problem-solving, training program development, and technology implementation projects requiring deep technical expertise.

How to Say Maintenance Abbreviations FAQ

What does MAINT mean in maintenance contexts?

MAINT serves as the standard abbreviation for maintenance across most industries and software systems. This four-letter designation appears in budgeting documents, computerized maintenance management systems, and scheduling platforms where character space limitations require abbreviated terminology while maintaining clear meaning.

How do emergency maintenance abbreviations differ from routine classifications?

Emergency maintenance abbreviations like EMER, URG, and CRIT indicate escalating priority levels that trigger specific response protocols and resource allocation decisions. These designations communicate urgency without ambiguity, enabling rapid decision-making during crisis situations where interpretation delays could compromise safety or operational continuity.

Why do maintenance professionals use abbreviations extensively?

Maintenance environments generate substantial documentation volumes while requiring rapid communication during emergency situations. Standardized abbreviations reduce documentation time, conserve character space in database systems, and ensure consistent interpretation across diverse workforce compositions and organizational levels.

What abbreviations appear most frequently in maintenance planning?

Planning abbreviations including SCHED, PLAN, BACKLOG, and OUTAGE facilitate coordination between maintenance teams, operations personnel, and management stakeholders. These designations streamline scheduling communication while distinguishing between different planning phases and resource allocation requirements.

How do international standards influence maintenance abbreviations?

Global standards organizations like ISO, ASME, and API establish abbreviation conventions that ensure consistent interpretation across international boundaries and industry sectors. These standardized approaches facilitate technology transfer, regulatory compliance, and professional mobility while reducing communication barriers in multinational organizations.

What role do digital technology abbreviations play in modern maintenance?

Technology abbreviations including IoT, RFID, AR, and ML reflect evolving capabilities that transform maintenance practices through automation, data analytics, and enhanced decision-making tools. Understanding these terms becomes essential as maintenance organizations integrate digital technologies to improve efficiency and reduce costs.

How do maintenance abbreviations vary across different industries?

Industry-specific abbreviations reflect unique operational requirements, regulatory environments, and safety considerations that influence communication patterns and documentation standards. Healthcare facilities emphasize precision and regulatory compliance, while manufacturing environments prioritize speed and standardization in abbreviation usage.

What training requirements exist for maintenance abbreviation proficiency?

Professional certification programs including CMRP and CRL incorporate abbreviation proficiency as essential knowledge components, recognizing that effective communication requires mastery of industry-standard terminology. Organizations typically provide orientation training covering internal abbreviation conventions alongside standard industry terminology.

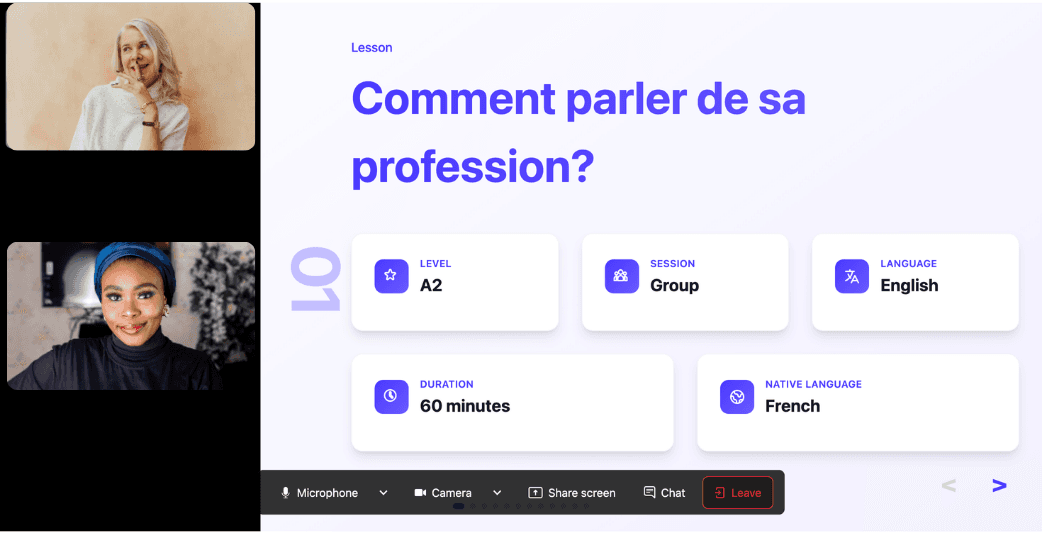

Learn Any Language with Kylian AI

Private language lessons are expensive. Paying between 15 and 50 euros per lesson isn’t realistic for most people—especially when dozens of sessions are needed to see real progress.

Many learners give up on language learning due to these high costs, missing out on valuable professional and personal opportunities.

That’s why we created Kylian: to make language learning accessible to everyone and help people master a foreign language without breaking the bank.

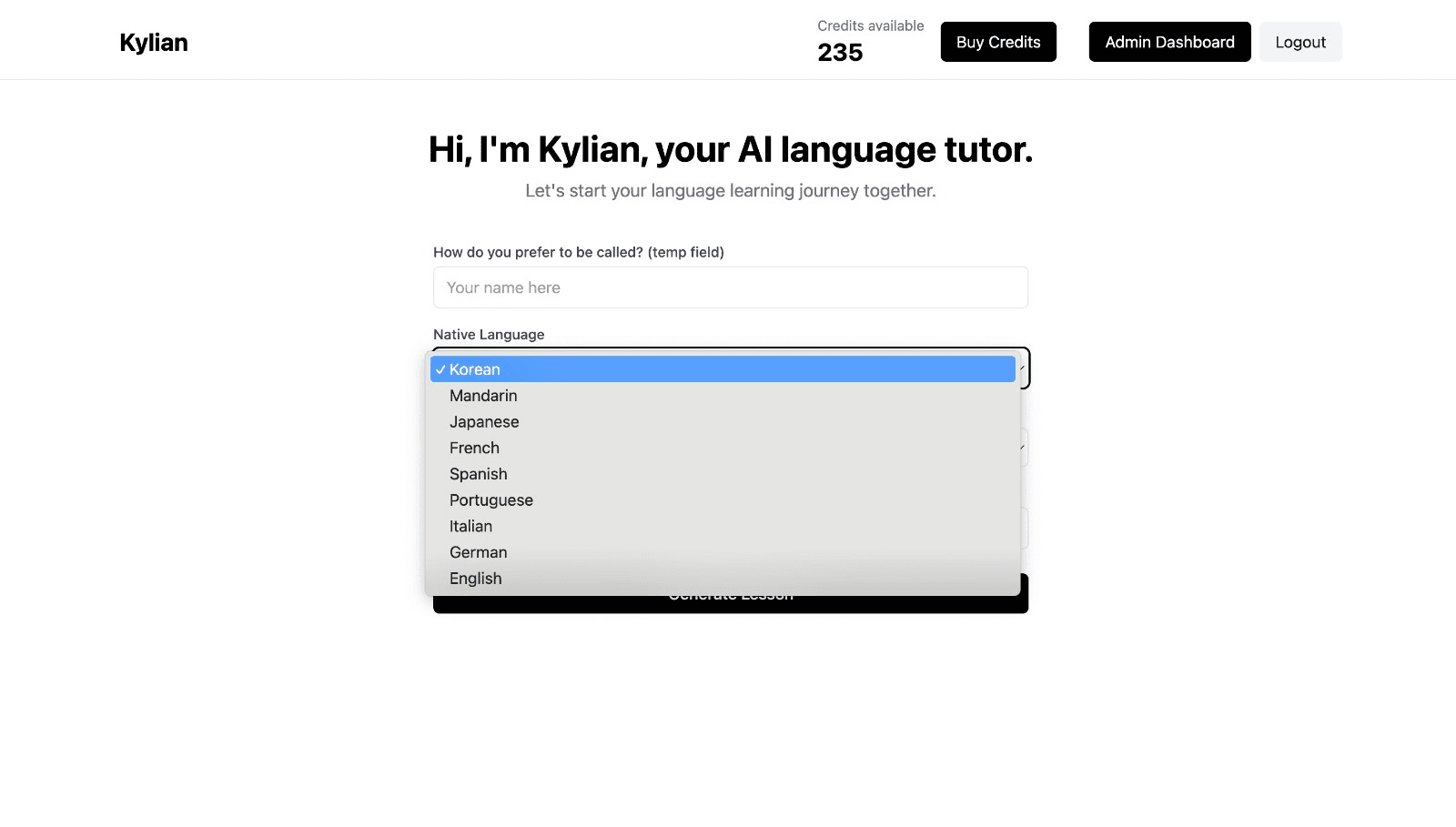

To get started, just tell Kylian which language you want to learn and what your native language is

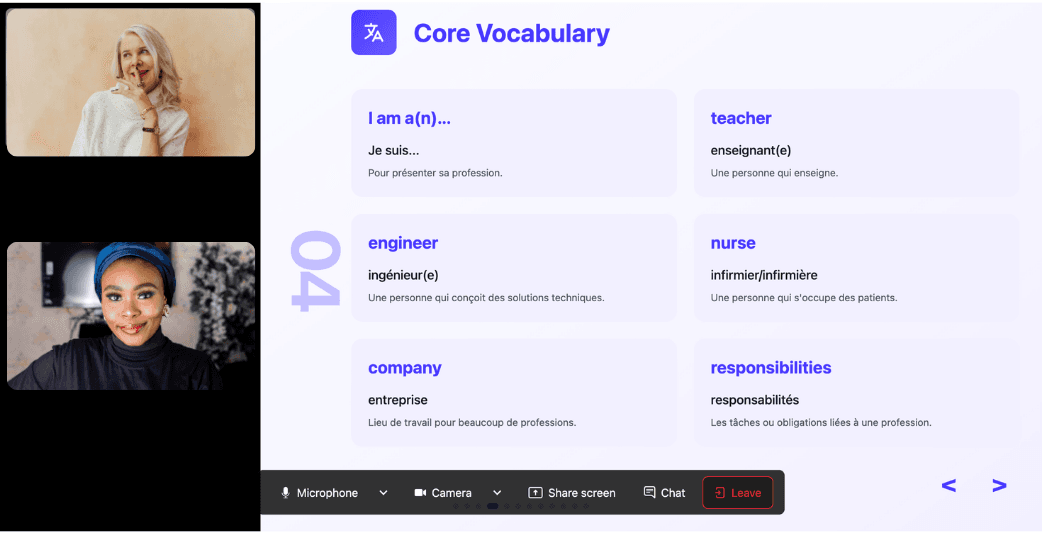

Tired of teachers who don’t understand your specific struggles as a French speaker? Kylian’s advantage lies in its ability to teach any language using your native tongue as the foundation.

Unlike generic apps that offer the same content to everyone, Kylian explains concepts in your native language (French) and switches to the target language when necessary—perfectly adapting to your level and needs.

This personalization removes the frustration and confusion that are so common in traditional language learning.

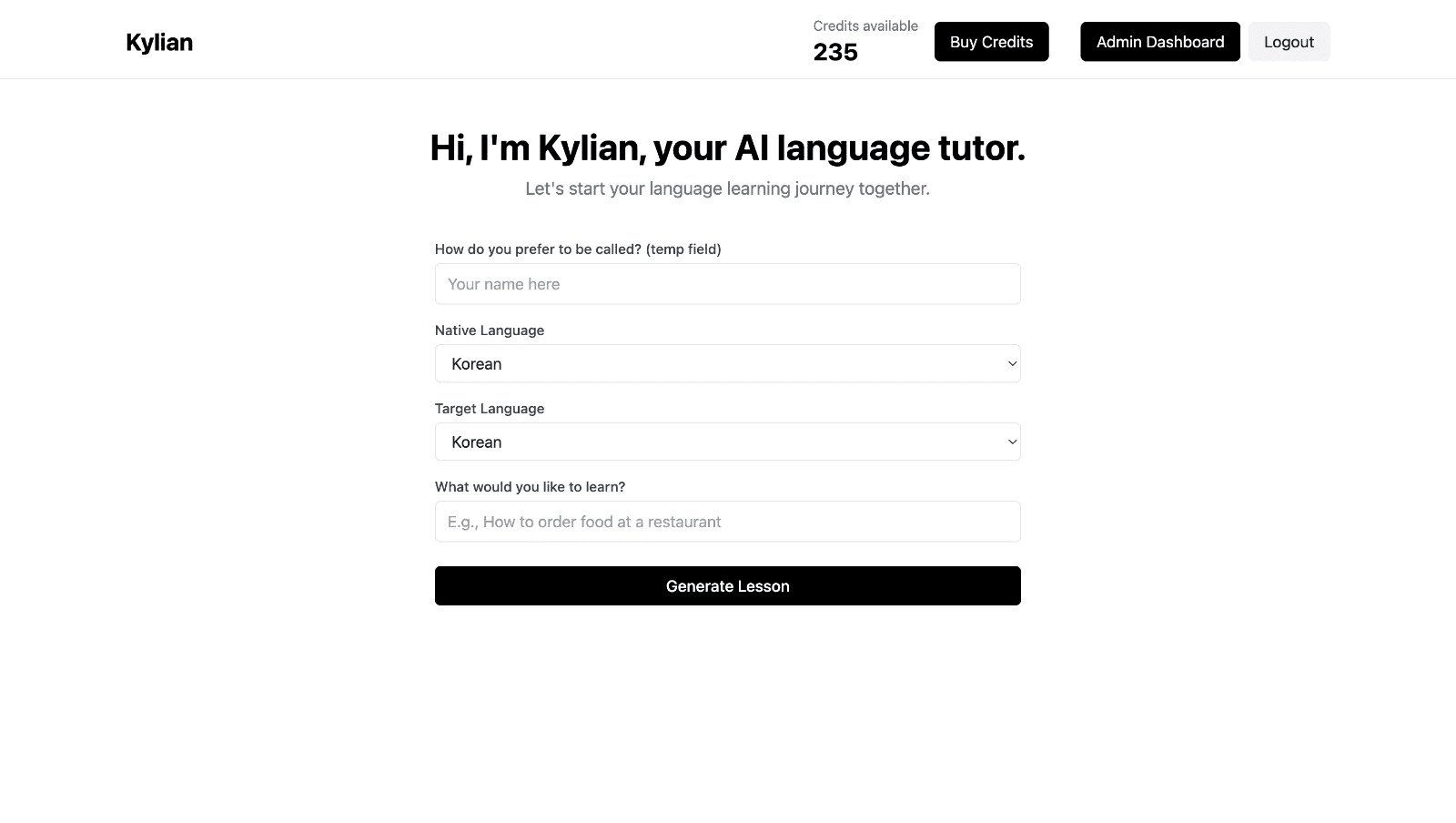

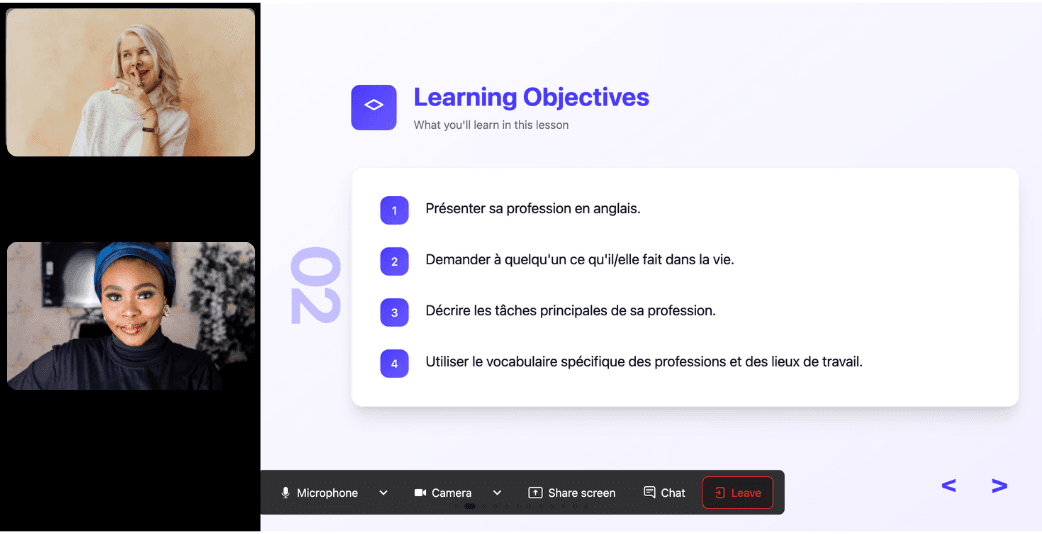

Choose a specific topic you want to learn

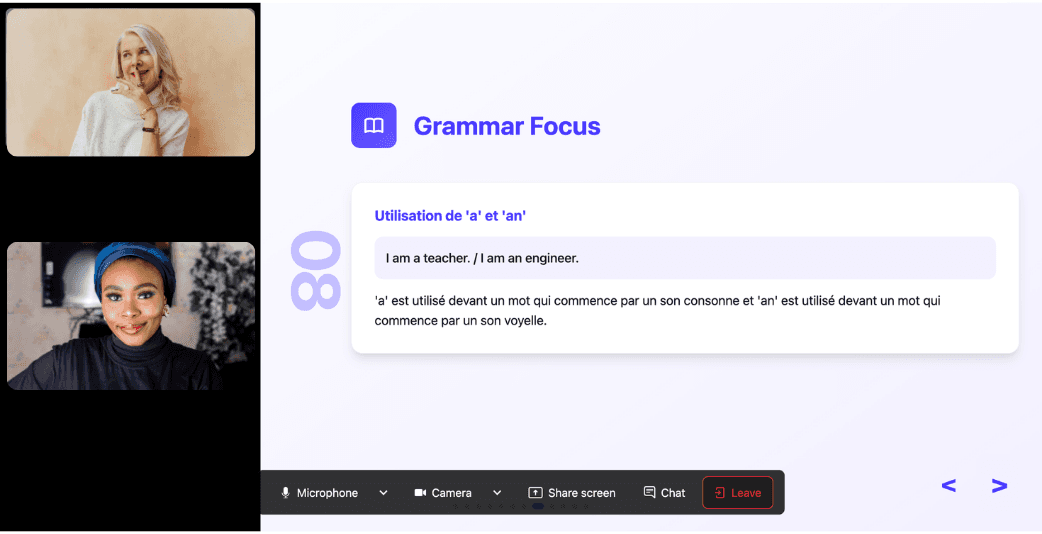

Frustrated by language lessons that never cover exactly what you need? Kylian can teach you any aspect of a language—from pronunciation to advanced grammar—by focusing on your specific goals.

Avoid vague requests like “How can I improve my accent?” and be precise: “How do I pronounce the R like a native English speaker?” or “How do I conjugate the verb ‘to be’ in the present tense?”

With Kylian, you’ll never again pay for irrelevant content or feel embarrassed asking “too basic” questions to a teacher. Your learning plan is entirely personalized.

Once you’ve chosen your topic, just hit the “Generate a Lesson” button, and within seconds, you’ll get a lesson designed exclusively for you.

Join the room to begin your lesson

The session feels like a one-on-one language class with a human tutor—but without the high price or time constraints.

In a 25-minute lesson, Kylian teaches exactly what you need to know about your chosen topic: the nuances that textbooks never explain, key cultural differences between French and your target language, grammar rules, and much more.

Ever felt frustrated trying to keep up with a native-speaking teacher, or embarrassed to ask for something to be repeated? With Kylian, that problem disappears. It switches intelligently between French and the target language depending on your level, helping you understand every concept at your own pace.

During the lesson, Kylian uses role-plays, real-life examples, and adapts to your learning style. Didn’t understand something? No problem—you can pause Kylian anytime to ask for clarification, without fear of being judged.

Ask all the questions you want, repeat sections if needed, and customize your learning experience in ways traditional teachers and generic apps simply can’t match.

With 24/7 access at a fraction of the cost of private lessons, Kylian removes all the barriers that have kept you from mastering the language you’ve always wanted to learn.

Similar Content You Might Want To Read

English Fat Slang: Master This English Expression

Days of the Week in English: Master Them with Ease

Learning the days of the week represents one of the fundamental building blocks of English language acquisition. Far from being mere calendar terms, these seven words serve as critical anchors for social coordination, professional communication, and cultural understanding. They interweave through daily conversations, music lyrics, business communications, and countless idiomatic expressions. This article explores the complete framework of the days of the week in English - from pronunciation guidance and etymological origins to cultural references and practical applications. By mastering these essential time markers, language learners gain a powerful tool for navigating English-speaking environments with confidence and precision.

Tagalog Speakers Worldwide: The Numbers and Impact

Tagalog serves as the linguistic backbone connecting millions across the globe to Filipino culture, heritage, and identity. Beyond being merely a communication tool, it represents the collective voice of a nation and its diaspora. Understanding its reach reveals not just numbers, but the story of migration, cultural preservation, and linguistic evolution in our increasingly connected society.

Austrian German vs. German: Key Differences & Dialects

Austrian German represents far more than a simple regional variation of Standard German. The linguistic landscape of Austria demonstrates how geography, history, and cultural identity shape language evolution in profound ways that impact daily communication, business interactions, and cultural understanding across German-speaking regions. The distinction between Austrian German and Standard German affects approximately 9 million Austrian speakers and carries implications for anyone engaging with Austrian markets, culture, or academic institutions. Understanding these differences eliminates communication barriers and demonstrates cultural competence that extends beyond basic language proficiency.

![Doomed Synonyms: 85+ Alternatives [Formal & Literary]](/_next/image?url=https%3A%2F%2Fcdn.sanity.io%2Fimages%2F147z5m2d%2Fproduction%2F46e49c7faa8c349b9f9d46f908ca3dea58c7e760-2240x1260.png%3Frect%3D175%2C0%2C1890%2C1260%26w%3D600%26h%3D400&w=3840&q=75)

Doomed Synonyms: 85+ Alternatives [Formal & Literary]

Language precision matters when conveying inevitability and fate. Writers, speakers, and communicators often search for alternatives to "doomed" that capture nuanced meanings across different contexts. The word "doomed" carries weight, but overuse dilutes its impact. Whether you're crafting academic prose, creative writing, or professional communication, selecting the right synonym elevates your message and demonstrates linguistic sophistication. In this article, we'll explore over 85 powerful alternatives to "doomed" across formal, literary, and contextual applications.

Countries That Speak Portuguese: A Global Language Guide

Have you considered where learning Portuguese might take you? Beyond the streets of Lisbon, this influential language opens doors across four continents, from the vibrant coastlines of Brazil to the serene landscapes of East Timor. Portuguese—a language with over 250 million speakers worldwide—serves as an official language in nine countries spanning Europe, South America, Africa, and Asia. Each region has developed its own dialect, infused with local culture and history, creating a rich tapestry of linguistic diversity. This comprehensive guide explores the global Portuguese-speaking landscape, examining how each country has shaped the language into something uniquely their own.